China’s germanium crisis looms: can recycling save the day?

GA, UNITED STATES, February 24, 2025 /EINPresswire.com/ -- A recent study reveals critical sustainability challenges for germanium (Ge), a vital metal used in advanced technologies such as infrared optics and solar cells. By 2050, China’s domestic demand for Ge is expected to double, yet a looming supply shortage before 2040 could disrupt industries reliant on the metal. Recycling efforts could only meet 30% of the growing demand, underscoring the need for better recycling technologies and strategic resource management.

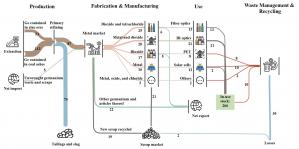

Germanium (Ge), a key semiconducting element, plays an essential role in industries ranging from fiber optics to solar cells. China, which produces 68% of the world's refined Ge, faces an unsustainable production model primarily dependent on zinc refining and coal ash. With global recovery rates of only 3%-5%, the country faces a growing demand-supply imbalance. This situation calls for urgent research to explore ways to enhance recycling and optimize resource use within the Ge supply chain.

Published (DOI: 10.1007/s11783-025-1945-3) in Frontiers of Environmental Science & Engineering on December 9, 2024, a study by Tsinghua University provides a comprehensive analysis of China's Ge flow system. The research uses substance flow analysis to project germanium demand and supply scenarios through 2050, showing a sharp increase in demand, particularly in the infrared optics and solar cell industries. The findings highlight an impending crisis, with the potential for a significant supply shortfall by 2040.

The study projects that by 2050, China's demand for Ge will soar to between 164–187 tons, driven by infrared optics, which will account for 62% of total demand, and solar cells at 24%. Despite recycling efforts, which could cover only 30% of the demand, supply gaps remain significant. The study predicts that while primary Ge production may reach 220 tons by 2050, nearly 80% of this will be consumed domestically. Current production and recycling systems are insufficient to meet future demand, and without advanced extraction and recycling technologies, a critical shortage is expected by 2040. Fiber optics and infrared optics offer the most promise for recycling, though current recovery rates remain low.

"Germanium is a critical metal with no easy substitutes in many high-tech applications," said Dr. Xianlai Zeng, lead author of the study. "Our findings underline the urgent need for better recycling technologies and more strategic resource management to ensure a stable supply. If we don't make significant strides, we risk facing a severe shortage that could disrupt multiple high-tech industries."

The study’s results have important implications for policymakers and industry leaders alike. To prevent a Ge crisis, the research recommends enhancing extraction and refining technologies to increase recovery rates. It also suggests focusing recycling efforts on infrared optics and fiber optics, which are projected to make up nearly 60% and 10% of the total scrap volume by 2050. The study advocates for policies that incentivize Ge recycling, such as tax breaks or subsidies for specialized enterprises. Additionally, integrating Ge recycling with other critical metals like gallium and rare earth elements could help mitigate global supply risks and support the transition to a circular economy.

DOI

10.1007/s11783-025-1945-3

Original Source URL

https://doi.org/10.1007/s11783-025-1945-3

Funding information

The work was financially supported by the National Natural Sciences Foundation of China (No. 92062111) and the National Key Technology R&D Program of China (No. 2019YFC1908501).

Lucy Wang

BioDesign Research

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.