CIMtech Green Energy Acquires Cypress Electronics' Injection Molding Division: A Green Revolution in Manufacturing

CIMtech Green Energy offers advanced low-volume injection molding services, ideal for rapid prototyping and high-precision production in various industries.

VANCOUVER, BRITISH COLUMBIA, CANADA, December 17, 2024 /EINPresswire.com/ -- CIMtech Green Energy, a recognized innovator in clean technology manufacturing, has taken a bold step toward transforming sustainable production by acquiring Cypress Electronics' injection molding division. This acquisition is more than a business decision—it’s a strategic investment in sustainable innovation aimed at revolutionizing the clean energy sector. By integrating Cypress Electronics’ technological expertise and infrastructure, CIMtech is set to elevate the manufacturing of critical components for hydrogen fuel cells, electrolyzers, and other advanced energy systems.Low-Volume Injection Molding for Rapid Prototyping and Production

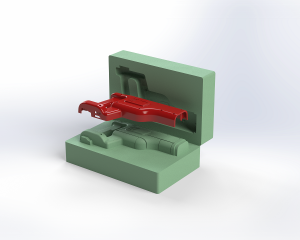

CIMtech Green Energy offers advanced low-volume injection molding services, ideal for rapid prototyping and high-precision production in industries such as automotive and hydrogen fuel cells. By leveraging 3D-printed molds, CIMtech ensures quick turnaround times, delivering high-quality injection molded parts in as little as two weeks. This rapid prototyping capability significantly accelerates the product development cycle, helping companies reduce time-to-market. With expertise in mold design analysis and Design for Manufacturability (DFM) feedback, CIMtech optimizes components for performance, manufacturability, and cost-effectiveness, making it an ideal partner for manufacturers seeking efficient and reliable plastic injection molding solutions.

CIMtech’s injection molding capabilities include both aluminum molds and steel molds, providing flexibility for production runs ranging from low-volume prototypes to large-scale production of up to one million units. This versatility allows CIMtech to meet diverse manufacturing needs, especially in the automotive industry and hydrogen fuel cell technology. The company works with a wide range of high-performance materials, including PVDF, ULTEM, PEEK, Delrin, and ABS, ensuring that parts meet the rigorous requirements of industries that demand durability and precision. Whether for prototype development or large-scale manufacturing, CIMtech’s injection molding services support efficient and cost-effective solutions, driving innovation in the fuel cell and automotive sectors.

Expanding Infrastructure and Capacity

The acquisition includes a state-of-the-art, 20,000-square-foot manufacturing facility in Surrey, British Columbia. This advanced facility positions CIMtech to become a leader in precision injection molding for low-volume, high-specification components. As global demand for clean energy technologies surges, particularly in the automotive, aerospace, and renewable energy industries, CIMtech's enhanced capabilities ensure it is well-equipped to meet this growing need.

Injection molding is crucial for producing lightweight, durable parts required in hydrogen technologies. This process minimizes material waste, accelerates production timelines, and ensures the consistency of high-quality components. Such advancements align with CIMtech’s broader mission to create sustainable solutions without compromising performance.

Strengthening Client Relationships

The acquisition empowers CIMtech to serve a diverse range of high-profile clients more effectively. With companies like Walmart and Amazon transitioning their fleets to hydrogen fuel cell technology, the demand for efficient and reliable components is skyrocketing. CIMtech’s advanced injection molding capabilities are integral to supporting these global leaders in achieving their sustainability and efficiency targets.

Additionally, CIMtech's partnerships with key industry players such as Ballard Power Systems demonstrate its critical role in shaping the future of clean energy. These collaborations underscore the company's influence in driving innovation and widespread adoption of hydrogen-based solutions.

Technological Innovation and Sustainability

CIMtech is embracing Industry 4.0 technologies to stay at the forefront of innovation. From real-time data monitoring to automated quality control systems, the integration of digital tools enhances the precision and efficiency of its manufacturing processes. These advancements are not only cost-effective but also contribute to environmental sustainability by minimizing energy use and waste.

Why This Matters

CIMtech Green Energy’s acquisition of Cypress Electronics' injection molding division signals a transformative moment for the clean energy manufacturing industry. By investing in advanced infrastructure and technologies, CIMtech is accelerating the adoption of hydrogen solutions across diverse sectors. This expansion is a significant step toward a more sustainable and technologically advanced future, enabling industries worldwide to transition to cleaner energy systems efficiently.

About Us: Advanced Manufacturing Capabilities

CIMtech has positioned itself as a premier provider of advanced manufacturing solutions for the automotive sector. The company offers a wide range of services, including precision CNC machining, injection molding, welding, fabrication, and 3D printing, all with a focus on meeting the automotive industry’s high standards. CIMtech’s capabilities in multi-axis CNC machining, 5-axis milling, CNC turning, and CNC grinding allow it to deliver high-quality solutions for automotive manufacturers, particularly those working in the hydrogen fuel cell space.

In addition to traditional manufacturing services, CIMtech offers cutting-edge additive manufacturing (3D printing) technologies, including FDM (Fused Deposition Modeling), SLA (Stereolithography), and metal printing. These technologies provide the flexibility needed for rapid prototyping, custom designs, and the creation of complex components with high precision. This makes CIMtech an ideal partner for automotive companies developing fuel cell systems, as well as those working on prototype and production runs.

CIMtech’s engineering team ensures that products meet both performance and manufacturing requirements. The team specializes in process optimization, material selection, and assembly techniques, ensuring that every component meets the highest quality standards. Whether optimizing a manufacturing process or developing new components, CIMtech’s engineers tackle the most complex challenges in the automotive sector.

One standout offering is CIMtech’s Zero Inventory Program, which helps automotive manufacturers optimize inventory management, reduce supply chain risks, and shorten lead times. This program allows clients to streamline production workflows and eliminate excess inventory, contributing to cost-saving initiatives while supporting the fast-paced demands of the fuel cell automotive industry.

Paul Ghotra

CIMtech Green Energy Mfg.Inc.

+1 604-575-8853

email us here

Visit us on social media:

Facebook

X

LinkedIn

Instagram

YouTube

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.