Thermal EOR Technology Safeguards Wells From Overheating

Game-changing CasingCooler™ enables thermal stimulation in otherwise at-risk environments.

GERI's CasingCooler™ is unique in its ability to provide precisely monitored and controlled wellbore cooling, which makes it a real game-changer.”

CALGARY, ALBERTA, CANADA, November 27, 2024 /EINPresswire.com/ -- Thermal oil recovery operations pose significant risks. Overheated wells can fail due to thermal stresses. This may result in safety or environmental impacts due to leaks, casing joint failure, or loss of formation cement integrity.— Chief Technology Officer, Brian Kay

GERI (General Energy Recovery Inc.) is presenting an innovation at the Society of Petroleum Engineers (SPE) Thermal Well Integrity and Production Symposium in Banff, December 2-5.

Along with its Direct Contact Steam Generation (DCSG), which simultaneously injects steam and flue gas, reducing carbon emissions, GERI's patented CasingCooler™ protects wells during thermal stimulation. These solutions were built for thermal recovery processes, including steam-assisted gravity drainage (SAGD), cyclic steam stimulation (CSS), and steam drive.

Chief Technology Officer, Brian Kay says there is nothing like it. "GERI's CasingCooler™ is unique in its ability to provide precisely monitored and controlled wellbore cooling, which makes it a real game-changer.”

INNOVATIVE TECHNOLOGY FOR THERMAL INJECTION WELLS

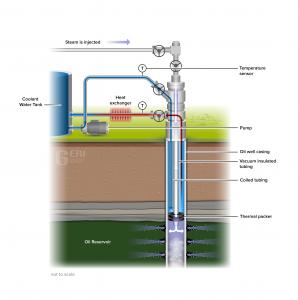

The CasingCooler™ complements the DCSG, which simultaneously injects high-quality steam and flue gases. It provides continuous cooling by protecting the wellbore casing and cement from extreme heat. This maintains structural integrity even in the absence of thermal cement. Stress related threats caused by extreme temperature fluctuations are mitigated.

Unlike traditional annular cooling methods, the CasingCooler™ actively circulates cooling fluid inside the casing. This creates a controlled closed-loop thermal barrier that limits casing and cement temperatures. GERI has rigorously tested and validated the technology in enhanced oil recovery (EOR) operations, where elevated temperatures and wellbore integrity is a challenge.

The CasingCooler™ has been proven to:

• regulate temperatures inside the casing, protecting it and surrounding cement from thermal stresses

• enable operators to push thermal performance boundaries without compromise

• allow thermal operations in existing cold heavy oil fields where wells have not been thermally cased/cemented

GERI is targeting heavy oil production regions in Alberta, specifically in Cold Lake, Peace River, Bonnyville, and Lloydminster. These areas are home to large scale thermal recovery projects, including SAGD and CSS, and cold heavy-oil production with sand (CHOPS) wells.

To find out more about the CasingCooler™ and GERI’s DCSG co-injector, start a conversation by emailing hello@geri.com today.

Diane Bennett, Senior PR Manager

GERI (General Energy Recovery Inc.)

+1 825-962-4374

dbennett@geri.com

Visit us on social media:

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.