ALEC² Helping Pilot Shipbuilding Industry Toward a Lighter and Fireproof Future With Unique Composite Material Option

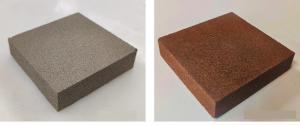

Disruptive ceramic composite material helps navigate ways to greater fire safety and lighter weights as a circular option for the shipbuilding world.

The shipbuilding industry faces a critical choice: prioritize weight, fire safety and the planet. ALEC² offers a solution that doesn't require compromise. ALEC² is playing a very important role.”

CALGARY, ALBERTA, CANADA, October 7, 2024 /EINPresswire.com/ -- ALEC² Helping Pilot the Shipbuilding Industry Towards Superior Fireproofing, Weight Reducing and the Circular Future with Revolutionary Ceramic Composite Material— Bill Hayward

The shipbuilding composite material landscape is shifting, with the industry facing a critical crossroads – balancing reducing weight and improving onboard fire safety with enhancing environmental performance. WT&C, a leading business development firm, is proudly helping to navigate this course by unveiling ALEC², a revolutionary ceramic composite material poised to reshape the future circularity of fireproof shipbuilding composite materials and sustainability.

Weight Reduction and Fireproof – A Marked Improvement in Light Weighting combined with Improving Fire Safety

ALEC² is a testament to material science ingenuity, boasting an unprecedented combination of fire proofing and remarkable lightness compared to steel and aluminum. Unlike traditional composites, ALEC² do not use any polymers, does not ignite or burn, offering unparalleled safety for ships’ crew and passengers:

• Zero Burn Rate – Upon contact with flame, ALEC² does not ignite and stops fire spread, ensuring vessel safety and the well-being of personnel onboard.

• Lightweight – Specific steel and aluminum applications can now use a unique composite, ALEC² that generates no flame, no toxic fumes or harmful chemicals during a fire event, further minimizing environmental impact awhile enhancing people and assets safety.

• Extreme Heat Resilience - With a softening temperature exceeding 1,000°C, ALEC² provides exceptional thermal insulation and is designed for surviving extreme fire and heat conditions.

ALEC² also has an incredibility lower density compared to steel, approximately one-fifth that of aluminum and one-third that of carbon fiber composites, which makes it a lightweight champion, paving the way for:

Fuel Efficiency Redefined

Lighter vessels mean reduced fuel consumption and diminished greenhouse gas emissions. This aligns seamlessly with the industry's push towards lower operating costs and increased sustainability.

Circular, Green and Sustainable - ALEC² Uses in a Circular Composite Economy

Beyond being an engineering feat, ALEC² is also new class of composite with complete circularity and promotes increased environmental responsibility. Created from ~85% recycled industrial waste, it paves the way for a sustainable future based on the core principles of the circular composite economy: 100% recyclable and reusable.

Seamlessly integrated with established recycling processes, ALEC² creates no waste while its reliance on recycled materials eliminates dependence on virgin resources, protecting the planet for generations to come.

Beyond its material science innovation, ALEC² champions and promotes environmental responsibility:

• Closed-Loop System - ALEC² operates in a closed-loop system, allowing for regeneration and reuse, eliminating the need for costly and complex open-loop recycling.

• Economic Viability - ALEC² is environmentally friendly and commercially viable, offering higher financial benefits and lower real cost (considering total system LCA) compared to incumbent composite technologies and metals.

• Simplification - ALEC²'s closed-loop system simplifies the recycling process, minimizing the need for challenging and uneconomical post-manufacturing recovery steps associated with currently used polymer-based composites.

ALEC²'s Versatility Sparks Innovation

ALEC²'s versatility makes it a game-changer for diverse shipbuilding applications:

- Nail-ability and Bondability - ALEC² integrates with existing construction methods, facilitating simple and seamless adoption and customization.

- Sandwich Structure Synergy - ALEC²'s adaptability allows for creating lightweight, fireproof sandwich structures. This makes it ideal for engine rooms, room panels, cargo containers and more.

- Suitable for Complex Shapes – ALEC² can be used for intricate molded designs with no or minimal pressure.

Future Proof Solution that Addresses Key Shipbuilding Industry Challenges

ALEC² is designed to provide a unique and significant improvement for the critical weight reduction combined with fireproofing material challenges faced by the shipbuilding industry:

Difficulties with Composites’ Circularity

ALEC²'s closed-loop system provides a solution to the complex, expensive and resource-intensive nature of recycling traditional composites.

ALEC²'s weight reduction and fireproof performance make it important in securing the future of the composites industry in shipbuilders’ environmentally footprint challenges and in our regulatory demanding world.

With ALEC², Fireproof and light weight combine into reality.

About WT&C

WT&C, a leading business development firm, partners with ARIS Inc., the visionary creators of ALEC², a disruptive and innovative fireproof and acoustic ceramic composite. Through collaborative efforts, WT&C empowers clients across shipbuilding, aerospace, and electrified transportation to achieve their innovation goals and build a better a safer and more sustainable future.

Bill Hayward

WT&C Innovates Inc.

+1 403-608-2449

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.