New VisionGauge® Thread Inspection Tool Provides Fast, Highly Accurate Results Directly from the Shop Floor

New VisionGauge® Thread Inspection tools are designed for fast & accurate automatic measurements on various types of parts with threads.

The mechanical advantage of threads is seen every day in millions of applications across a wide range of industries, from precision bone screws in Medical Manufacturing for orthopedic implants, to pipe fittings in the Oil and Gas industry critical for environmental protection, and the widespread presence of critical threaded parts in the Aerospace and Energy/Power industries. Thorough and reliable inspection is required in certain applications where failure could lead to disaster as these simple fasteners can undergo such high amounts of stress. As threads become even more complex, they concurrently become even more challenging to machine as tighter tolerances are continuously demanded by design engineers. Manufacturers are thus challenged with assuring quality on tighter tolerances all the while trying to maintain or increase throughput, hence thread inspection is becoming ever more important.

The new VisionGauge® Thread inspection tool is now available for both manual operator measurements on a part-by-part basis and in complete automated programs that can carry out multiple inspections and measurements, reporting, stage/part positioning and part changeover, and full process automation. VisionGauge® Digital Optical Comparators can be used as a complete inspection and measurement system directly from the shop floor.

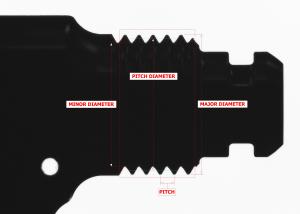

The VisionGauge® Thread Inspection tool supports various feature measurements, including:

• Average minor diameter

• Average major diameter

• Average pitch diameter

• Minimum pitch diameter

• Maximum pitch diameter

• Average pitch

Specific locations calculated from the measurements can also be saved as Datums for re-use in further measurements. A supplementary rotary stage can also be recruited to easily obtain thread runout using the saved centers of the threads.

Setup and operation for thread measurements is extremely quick and intuitive: Simply select the feature measurements required (plus any tolerances for Pass/Fail results and reporting specifications) and the region of interest surrounding the top and bottom threads to be measured. Execution depends on the size of the region chosen and generally takes less than a second. Complete results can be output to various channels (collected in Data Groups, sent to Excel, SPC software, text file, etc.).

The new VisionGauge® Thread Inspection tool replaces thread ring gages and plug gages used as a simple GO/NO-GO gage, while overcoming their limitations for use with a specific thread size and the difficult, expensive process of recalibrating each gage after shop floor usage.

The VisionGauge® Thread Inspection tool also provides significant advantages over the three-wire method, also known as measurement over wires, used to measure the pitch diameter of external threads. In that approach a regular micrometer is used to measure the distance between the two top wires and bottom wire, and then a chart is referenced along with some calculations to obtain the pitch diameter. While this alternative is certainly the cheapest, it does require practice as measurements can be influenced by the inspector. These inspection methods provide very limited data to be transmitted back to the machine to ensure the process remains on course and may only detect unwanted trends later than desired... For higher levels of precision and deeper analysis, a contour tracer or even a CMM may be used to measure threads, since these systems can create a trace of the actual thread profile. The main disadvantage here is the inspection time drastically increases in relation to the methods commonly used.

The VisionGauge® Digital Optical Comparator's Thread Measurement tool offers the best of both worlds, as it can automatically collect and database the desired thread measurement data for traceability all the while reducing the inspection time with operator independent results, perfect for high-volume production speeds.

To learn more about VisionGauge® systems and software, please contact VISIONx, Inc., either by visiting www.visionxinc.com or by emailing info@visionxinc.com.

VISIONx INC. specializes in automated imaging, visual inspection and high accuracy measurement solutions sold worldwide and is the manufacturer of the VisionGauge® Digital Optical Comparator.

Patrick Beauchemin

VISIONx, Inc.

+1 514-694-9290

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

YouTube

New VisionGauge® Threads Inspection and Measurement Overview and Demonstration Video - Fast, Easy, and Accurate

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.