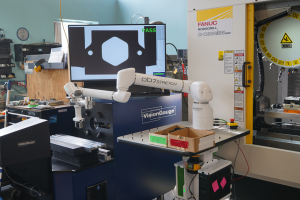

New VisionGauge® Automation Module for Direct Machine Interface Integrates Quality Inspection Into Industrial Automation

The new VisionGauge® Automation Module allows manufacturers to increase productivity by including quality inspection and measurements in the production line.

The VisionGauge® Digital Optical Comparator is fast, accurate, and requires virtually no programming. The VisionGauge® Digital Optical Comparator allows manufacturers to achieve significant gains in throughput. The system produces demonstrated accuracy down to +/-0.0001" in real-world applications, right on the production floor. It can display deviations from nominal completely automatically and can be used to create automated inspection reports and collect complete device history.

Up until now, most implementations of the VisionGauge® Digital Optical Comparator involved some kind of operator intervention, most often for the loading and unloading of parts. Today, we are pleased to introduce the VisionGauge® Automation Module that allows the system to very easily be interfaced to any type of external machinery, such as an automated cell controller or a robot for part loading & unloading.

The VisionGauge® Automation Module includes all the necessary hardware & software for full 2-way Ethernet (over TCP/IP) communication as well as 2-way I/O communication (over up to 48 channels) between external machinery and VisionGauge®.

It also includes an E-Stop that, when triggered, will immediately stop all motion as well as terminate the execution of any program. With the new VisionGauge® Automation Module, everything about the system’s execution can be controlled externally, for full “lights out” operation.

VisionGauge’s® high-accuracy measurements can also be used to send feedback and offsets to controllers for fully automated offset correction. VisionGauge® systems are very widely applicable and extremely general-purpose. They are perfect for carrying out very high-accuracy inspections & measurements in fully automated applications. And thanks to its extensive data collection, manipulation & exchange, statistics, charting, databasing and reporting capabilities, VisionGauge® can give manufacturers a complete picture of production results during long automated runs.

This new VisionGauge® Automation Module is keeping VisionGauge® at the forefront of the automation revolution. It allows manufacturers to increase productivity, reduce costs, overcome labor scarcity, and get all the benefits of VisionGauge®, 24/7. It allows manufacturers to gain a real advantage in today's competitive market by including high-accuracy quality inspection and measurement directly into the production line.

The new VisionGauge® Automation Module is a simple, cost-effective “out of the box” solution that allows manufacturers to integrate the VisionGauge® Digital Optical Comparator into their automated production cell very quickly and easily.

To learn more about the benefits of the VisionGauge® Digital Optical Comparator, please contact us, either by visiting our web site at www.visionxinc.com or by emailing us at info@visionxinc.com.

VISIONx INC. specializes in automated imaging, visual inspection and high accuracy measurement solutions sold worldwide and is the manufacturer of the VisionGauge® Digital Optical Comparator.

Patrick Beauchemin

VISIONx, Inc.

+1 514-694-9290

info@visionxinc.com

Visit us on social media:

Facebook

Twitter

LinkedIn

YouTube

VisionGauge Automation Module Directly Interfaces with External Machinery for Inline Quality Inspection

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.