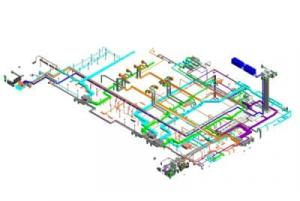

MEP BIM Coordination Services, Enhancing Construction Project Workflow

Electrical BIM Model

Plumbing Modeling through BIM

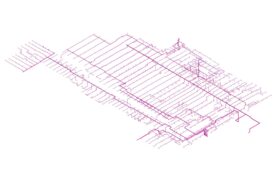

Fire Protection Modeling through BIM

Implementing MEP BIM Coordination, engineers detect constructibility issues at pre-construction, improving building design, decreasing project time & cost.

Facts about BIM MEP Coordination Services:

· Mechanical, Electrical, Plumbing & Fire Protection systems call for around 60% of the building project cost.

· As per a global survey in 2016, half of the contractors with $50-million implemented BIM technology.

· The same survey confirmed that about 41% of contractors use BIM coordination drawings in their construction workflow.

What is BIM MEP Coordination?

A Building Information Modeling based technique enables collaboration amongst Mechanical, Electrical and Plumbing services. The method identifies and resolves conflicts amongst architectural, structural as well as mechanical, electrical, plumbing and fire protection services at the pre-construction stage. Consequently, this leads to synchronized design coordination from the conceptual, schematic & detailed design to the stage of final construction documentation.

Importance of MEP Coordination:

The importance of MEP BIM services lies in clash detection with the help of coordinated drawings produced from the 3D model. Accurate MEP BIM models facilitate clash detection through:

ü Detecting design mismatches in the construction schedule, sections, risers as well as architectural, structural & MEPF drawings

ü Identifying the need for revising diffuser and ceiling light layout

ü Raising constructability issues through RFIs and updating MEP models & shop drawings

ü Finding out space constraints, saving rework, time and eradicating project wastage

Thoughts of a BIM Specialist:

Regarding the Significance, a Project Manager in the USA explained – "Our MEP engineers respond to all RFIs from clients and resolve clashes at pre-construction through duct re-routing, elevation change, as well as duct resizing. We follow SMACNA standards and other local codes based on project requirements. The quality control process facilitates documenting client standards and preferences. We ensure compliance check to make MEP models free from clashes, with the least scope of rework."

Benefits of MEP Coordination Services:

· Clash-Free Design: An accurate coordination leads to clash-free designs. A model is sent to Navisworks software application for clash check, resolving significant changes in the model.

· Reduced Rework: MEP BIM modeling reduces project rework, minimizing wastage through clash detection at the pre-construction stage. An early-stage design collaboration with BIM helps construction professionals to work effectively, minimizing errors at later stages of construction.

· Construction Cost Savings – BIM facilitates construction twice, initially as a ‘model with data’ and later ‘on the site’. This enables real-time construction workflow compared to the on-site modifications. Integrating BIM in the workflow, BIM modelers reduce material wastage and labor, saving long-term project costs.

· Decreased Material Wastage – A real-time coordination decreases material wastage through inaccuracies during the later stage of construction, as clashes are resolved during the design-build stage.

Stages of MEP Design Coordination in Construction:

· Model Creation – BIM modeling companies make effective project coordination through Revit. Once the model is created, HVAC, Electrical & Plumbing components remain integrated with the architectural and structural models.

· Clash Detection – BIM integrated MEP coordination enables clash detection amongst Mechanical, Electrical and Plumbing components. Conflicts amongst architectural, structural and MEP services are sorted out, leading to smooth clash resolution.

· Coordination Drawing Preparation – BIM modelers create coordinated drawings like elevation and section drawings from the 3D models. MEP drawings provide information about MEP members, helping clients understand integrated components within the allotted space.

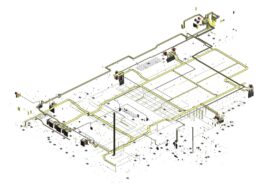

· Service Drawing Creation – The building drawings encompass detailed information about the MEP components, including size, height and distance from gridlines. Once the service drawings are completed, they are sent for on-site installation.

· Fabrication Drawing Formation – The fabrication drawings reveal fabrication details of the Mechanical, Electrical and Plumbing systems along with their associated components such as HVAC ducts, pipes, electrical, as well as fire protection systems.

· As-built Drawings – The very last stage involves the creation of as-built drawings, with information about modifications made to 3D models, including site-based changes.

What do the MEP BIM Consultants say?

An experienced BIM consultant in USA explained the process:

“ We provide 3D BIM models of Mechanical (HVAC), Electrical & Plumbing Services, using contract & design documents, specification sheet & submittals. A team of engineers validates the MEP design at the pre-construction stage, resolving clashes for smooth construction. Using BIM software like Revit, AutoCAD, etc. enable Modelers, Architects, & Engineers work in a streamlined manner."

The crux of the matter:

BIM-based design and construction are an essential part of Virtual Design & Construction. This enables data-driven collaboration amongst stakeholders, enhancing the design-build process. Engineers working with BIM for MEP coordination drawings produce 3D models within a quick turnaround time. The technique improves building design & quality, decreasing project time and costs. Hence, MEP coordination is very significant in making a strong building.

Want to facilitate collaboration amongst MEP engineering, structural engineering and architectural plans? Get in touch with the best BIM company and obtain MEP Coordination services to obtain a streamlined project workflow.

Take a look at the MEP Projects of Tejjy Inc. BIM Service Provider in USA

· Building 213 Water Purification Plant – 3d Modeling with Fabrication Shop Drawings Creation at LOD 450 for on-site coordination and quantity take-off from approved material submittal.

· DC Court-House Project – BIM modelers worked with software applications like Revit, Navisworks, Fabrication and PDF viewer for 3D model creation & clash detection of MEPF services, constructability reviews, error-free coordinated shop drawing production and detailed quantity take-off of the DC Courthouse Project.

sukhchain singh

Tejjy Inc.

+1 2405954210

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

BIM Clash Detection and Clash Coordination Services - Tejjy Inc.

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.