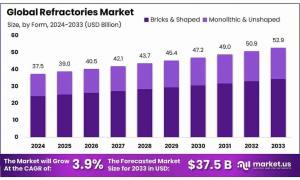

Refractories Market to Reach USD 52.9 Billion by 2033, Growing at a 3.9% CAGR from USD 37.5 Billion

Refractories Market size is expected to be worth around USD 52.9 billion by 2033, from USD 37.5 billion in 2023, growing at a CAGR of 3.9%

Asia-Pacific holds the largest market share at 43.4% in 2023, valued at USD 16.3 billion, driven by rapid industrial growth in China and India.

”

NEW YORK, NY, UNITED STATES, January 31, 2025 /EINPresswire.com/ -- Overview— Tajammul Pangarkar

The global refractories market is projected to expand from USD 37.5 billion in 2023 to approximately USD 52.9 billion by 2033, growing at a CAGR of 3.9%. Refractories are heat-resistant materials used in lining furnaces, kilns, and reactors, crucial to industries such as steel, cement, and glass manufacturing. The market's growth is driven by factors such as advancements in refractory materials promoting energy efficiency and environmental sustainability. The demand in the Asia-Pacific region is particularly robust, fueled by rapid industrialization in countries like China and India. Technologies enhancing resistance to high temperatures and improving durability are at the forefront, catering to strict regulations and emission standards, especially in Europe. Investments in this market underscore a trend towards environmentally friendly solutions, highlighting the sector's dynamic and competitive environment.

Key Takeaways

• The global refractories market is projected to grow from USD 37.5 billion in 2023 to USD 52.9 billion by 2033, with a 3.9% CAGR.

• Asia-Pacific holds the largest market share at 43.4% in 2023, valued at USD 16.3 billion, driven by rapid industrial growth in China and India.

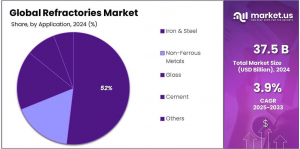

• The iron and steel sector represented 55.4% of market demand in 2023, being the largest consumer of refractories for furnace and high-temperature applications.

• In 2023, Bricks & Shaped refractories captured over 65.4% of the market due to their widespread use in kilns, furnaces, and high-temperature settings.

• Clay refractories accounted for 58.5% of the product market in 2023, largely due to their high resistance and cost-effectiveness in the steel industry.

• Urbanization in emerging economies, projected to reach 68% globally by 2050, is driving demand for refractories in construction, metals, and cement industries.

• Global investments in refractory technology upgrades and capacity expansion reached $1.5 billion in 2023, emphasizing innovation and energy-efficient solutions.

👉 Request a free sample PDF report for valuable insights: https://market.us/report/refractories-market/request-sample/

Experts Review

• Government Incentives and Technological Innovations: Governments, particularly in emerging economies, are investing significantly in infrastructure development, boosting refractories demand. Technological advancements are focusing on eco-friendly, non-carbon-based refractories, aligning with global sustainability goals.

• Investment Opportunities & Risks: With a robust investment trend, opportunities are abundant, especially in energy-efficient technologies. However, compliance with stringent environmental regulations poses investment risks, potentially increasing operational costs.

• Consumer Awareness: Rising awareness about environmental impacts and operational efficiency is steering consumer demand towards sustainable refractory solutions.

• Technological Impact: Innovations in refractory technology are crucial in reducing energy consumption and improving thermal management, making high-performance materials essential across industries.

• Regulatory Environment: Stringent regulations globally are mandating reductions in emissions, compelling manufacturers to innovate, develop cleaner technologies, and use sustainable materials, influencing market dynamics.

Report Segmentation

The refractories market is segmented by form, product, alkalinity, fusion temperature, manufacturing process, and end-use industry. By form, bricks and shaped refractories remain dominant due to their durability, while monolithic varieties are gaining traction for their adaptability. Product segmentation includes clay and non-clay refractories, each catering to specific industrial needs. Refractories are also categorized by alkalinity into acidic, neutral, and basic, with acidic & neutral dominating due to their resistance properties. Fusion temperature segments include normal, high, and super refractories, crucial for high-temperature industries like steel and non-ferrous metals. Manufacturing processes involve dry press, fused cast, and hand-molded techniques, each offering unique benefits. End-use industries are diverse, spanning iron and steel, non-ferrous metals, glass, and cement, each demanding specific refractories for optimized performance.

Key Market Segments

By Form

• Bricks & Shaped

• Monolithic & Unshaped

By Product

• Clay

• Non-Clay

By Alkalinity

• Acidic & Neutral

• Basic

By Fusion Temperature

• Normal Refractory (1580-1780 °C)

• High Refractory (1780-2000 °C)

• Super Refractory (>2000 °C)

By Product

• Castables & Mortars

• Ceramic Fibers & Firebricks

• Graphite Blocks

• Insulation Fire Brick

By Manufacturing Process

• Dry Press Process

• Fused Cast

• Hand Molded

• Formed

• Unformed

By End-Use Industry

• Iron & Steel

• Non-Ferrous Metals

• Glass

• Cement

• Others

👉 Buy Now to access the full report: https://market.us/purchase-report/?report_id=128666

Drivers, Restraints, Challenges, and Opportunities

• Drivers: The refractories market is primarily driven by increasing demands in the steel and cement industries, rapid industrialization in Asia-Pacific, and advancements in environmentally sustainable technologies.

• Restraints: Stringent environmental regulations worldwide necessitate significant compliance investments, potentially pushing up production costs and impacting market growth.

• Challenges: The main challenges include developing alternative technologies and addressing compliance costs due to strict emissions mandates.

• Opportunities: Rising demand in the aerospace sector for high-temperature applications and government investments in defense and infrastructure projects create growth opportunities. Technological innovations, particularly in sustainable materials, present further potential.

Key Player Analysis

Prominent players in the refractories market include RHI Magnesita, Vesuvius, and Saint-Gobain, renowned for their innovative solutions and robust global networks. These companies dominate especially in regions like Asia-Pacific and Europe, where industrial applications in steel, cement, and glass demand high-quality refractories. POSCO Future M Co., Ltd., KEFER SE & Co., KG, and others also hold significant shares due to their specialized high-performance materials. Companies like HarbisonWalker International and Intocast Group are also influential, driven by their strong presence in North America and Europe, meeting growing demands in the steel and aerospace industries.

Key Market Players

• Saint-Gobain

• Imerys

• RHI Magnesita

• POSCO Future M Co., Ltd.

• KEFER SE & Co. KG

• Beijing Lier High-Temperature Materials Co., Ltd.

• HarbisonWalker International

• Intocast Group

• Alsey Refractories Co.

• Magnezit Group

• Vesuvius

• Puyang Refractories Group Co., Ltd.

• Refratechnik Holding GmbH

• Ruitai Materials Technology Co., Ltd.

• Plibrico Company, LLC

Recent Developments

In 2023, major players such as Saint-Gobain and Imerys have focused on expanding their product lines and operational capabilities. Saint-Gobain has enhanced its presence in industries like steel and cement, emphasizing innovative, high-performance refractories. Imerys is expanding its alumino-silicate and magnesia-based products to meet the increasing demand, particularly in the Asia-Pacific region, highlighting a strategic shift towards addressing regional growth and operational efficiencies.

Conclusion

The refractories market is poised for steady growth driven by technological innovations, regulatory changes, and robust industrial demand, especially in rapidly developing regions. Increasing emphasis on sustainability and efficiency within the industry presents both challenges and opportunities. Market players must focus on innovation and compliance to harness these trends and drive growth.

Lawrence John

Prudour

+91 91308 55334

Lawrence@prudour.com

Visit us on social media:

Facebook

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.