Laser Cutting Machines Market Scope Trends and Size Insights with Demand Forecast for 2034

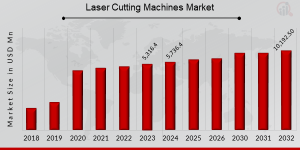

NEW YORK, NY, UNITED STATES, January 13, 2025 /EINPresswire.com/ -- The Laser Cutting Machines Market was valued at USD 5,316.4 million in 2023. It is expected to increase from USD 5,736.4 million in 2024 to USD 10,192.50 million by 2032, with a CAGR of 7.4% during the forecast period from 2024 to 2032.

The laser cutting machines market is a vital segment of the manufacturing industry, providing precision cutting solutions for various materials, including metals, plastics, wood, and textiles. Laser cutting technology is favored for its accuracy, speed, and ability to create intricate designs, making it an essential tool in industries such as automotive, aerospace, electronics, and construction.

Current Trends

Recent trends in the laser cutting machines market include advancements in laser technology, the rise of automation and Industry 4.0, and increasing demand for customized solutions. The integration of artificial intelligence (AI) and machine learning into laser cutting processes is also enhancing operational efficiency and precision.

📍 Get Free Sample Report for Detailed Market Insights: https://www.marketresearchfuture.com/sample_request/6894

Market Drivers

Growing Demand from End-User Industries

The demand for laser cutting machines is primarily driven by their extensive applications across various sectors. Industries such as automotive and aerospace require high precision and quality in their manufacturing processes, which laser cutting technology can provide.

Technological Advancements

Innovations in laser technology, such as fiber lasers and ultrafast lasers, are improving cutting speeds, accuracy, and material versatility. These advancements make laser cutting machines more attractive to manufacturers seeking efficient production methods.

Rising Focus on Automation

The trend towards automation in manufacturing processes is driving the adoption of laser cutting machines. Automated systems reduce labor costs and increase production efficiency, making them appealing to manufacturers looking to optimize their operations.

Key Companies

Several key players dominate the laser cutting machines market, each contributing uniquely to its growth:

Trumpf GmbH + Co. KG

Contribution: A leading manufacturer of laser cutting machines, Trumpf offers a wide range of products known for their quality and innovation.

Competitive Advantage: Strong focus on R&D and advanced technology positions them as industry leaders.

CNC Systems

Contribution: Specializes in CNC laser cutting machines and automation solutions for various industries.

Competitive Advantage: Their expertise in custom solutions enhances their competitive edge.

Bystronic AG

Contribution: Bystronic provides advanced laser cutting and bending solutions, catering to diverse manufacturing needs.

Competitive Advantage: Their comprehensive service offerings and customer support strengthen their market position.

Amada Co., Ltd.

Contribution: A major player in the sheet metal processing industry, Amada offers a range of laser cutting machines and automation systems.

Competitive Advantage: Their extensive product portfolio and global presence enhance their competitiveness.

Mitsubishi Electric Corporation

Contribution: Mitsubishi Electric manufactures high-performance laser cutting machines known for their reliability and precision.

Competitive Advantage: Strong brand reputation and technological expertise contribute to their market success.

🛒 You can buy this market report at: https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=6894

Market Restraints

Despite its growth potential, the laser cutting machines market faces several challenges:

High Initial Costs

The upfront investment required for laser cutting machines can be substantial, which may deter small and medium-sized enterprises from adopting this technology.

Technical Complexity

Operating and maintaining laser cutting machines requires specialized knowledge and skills. The complexity of these machines can lead to challenges in training staff and ensuring optimal performance.

Competition from Alternative Cutting Technologies

Laser cutting faces competition from other cutting technologies, such as plasma and waterjet cutting. These alternatives may be preferred in certain applications due to cost or specific material requirements.

Market Segmentation Insights

The laser cutting machines market can be segmented based on various criteria:

Technology Type

CO2 Lasers: Widely used for cutting non-metal materials and some metals, known for their versatility.

Fiber Lasers: Increasingly popular for metal cutting due to their efficiency and speed.

Solid-State Lasers: Used for high-precision applications, particularly in the electronics industry.

Application

Metal Cutting: The largest segment, driven by demand from industries such as automotive and aerospace.

Non-Metal Cutting: Growing demand in industries like textiles and woodworking.

Medical Device Manufacturing: Increasing use of laser cutting in the production of medical devices due to precision requirements.

Geographic Regions

North America: A mature market with strong demand from the automotive and aerospace sectors.

Europe: Significant growth driven by advancements in manufacturing technologies and automation.

Asia-Pacific: Rapid industrialization and rising manufacturing activities present significant opportunities for market expansion.

To explore more market insights, visit us at: https://www.marketresearchfuture.com/reports/laser-cutting-machines-market-6894

Future Scope

The future of the laser cutting machines market looks promising, with several emerging trends and innovations on the horizon:

Emerging Trends

Industry 4.0 Integration: The adoption of smart manufacturing practices, including IoT and AI, will enhance the efficiency and capabilities of laser cutting machines.

Customization and Flexibility: Increasing demand for customized solutions will drive manufacturers to develop more adaptable laser cutting systems.

Innovations

Hybrid Laser Cutting Systems: The development of hybrid systems that combine different cutting technologies will provide greater versatility and efficiency.

Enhanced Software Solutions: Advances in software for design and operation will improve the user experience and operational efficiency of laser cutting machines.

Growth Opportunities

Emerging Markets: Growing manufacturing sectors in developing countries present significant opportunities for market expansion.

Sustainability Initiatives: The increasing focus on sustainable manufacturing practices will drive demand for efficient and eco-friendly cutting technologies.

The laser cutting machines market is poised for continued growth, driven by increasing demand from end-user industries, technological advancements, and the rise of automation. While challenges exist, the potential for innovation and market expansion presents exciting opportunities for manufacturers and investors alike.

More Related Reports from MRFR Library:

Industrial Valves Actuators Market: https://www.marketresearchfuture.com/reports/industrial-valves-actuators-market-23568

Reels And Spools Market: https://www.marketresearchfuture.com/reports/reels-spools-market-23575

Sand Blasting Machine Market: https://www.marketresearchfuture.com/reports/sand-blasting-machine-market-23508

Valves And Actuators Market: https://www.marketresearchfuture.com/reports/valves-actuators-market-23545

Powered Lawn Mower Market: https://www.marketresearchfuture.com/reports/powered-lawn-mower-market-23599

The laser cutting machines market is a vital segment of the manufacturing industry, providing precision cutting solutions for various materials, including metals, plastics, wood, and textiles. Laser cutting technology is favored for its accuracy, speed, and ability to create intricate designs, making it an essential tool in industries such as automotive, aerospace, electronics, and construction.

Current Trends

Recent trends in the laser cutting machines market include advancements in laser technology, the rise of automation and Industry 4.0, and increasing demand for customized solutions. The integration of artificial intelligence (AI) and machine learning into laser cutting processes is also enhancing operational efficiency and precision.

📍 Get Free Sample Report for Detailed Market Insights: https://www.marketresearchfuture.com/sample_request/6894

Market Drivers

Growing Demand from End-User Industries

The demand for laser cutting machines is primarily driven by their extensive applications across various sectors. Industries such as automotive and aerospace require high precision and quality in their manufacturing processes, which laser cutting technology can provide.

Technological Advancements

Innovations in laser technology, such as fiber lasers and ultrafast lasers, are improving cutting speeds, accuracy, and material versatility. These advancements make laser cutting machines more attractive to manufacturers seeking efficient production methods.

Rising Focus on Automation

The trend towards automation in manufacturing processes is driving the adoption of laser cutting machines. Automated systems reduce labor costs and increase production efficiency, making them appealing to manufacturers looking to optimize their operations.

Key Companies

Several key players dominate the laser cutting machines market, each contributing uniquely to its growth:

Trumpf GmbH + Co. KG

Contribution: A leading manufacturer of laser cutting machines, Trumpf offers a wide range of products known for their quality and innovation.

Competitive Advantage: Strong focus on R&D and advanced technology positions them as industry leaders.

CNC Systems

Contribution: Specializes in CNC laser cutting machines and automation solutions for various industries.

Competitive Advantage: Their expertise in custom solutions enhances their competitive edge.

Bystronic AG

Contribution: Bystronic provides advanced laser cutting and bending solutions, catering to diverse manufacturing needs.

Competitive Advantage: Their comprehensive service offerings and customer support strengthen their market position.

Amada Co., Ltd.

Contribution: A major player in the sheet metal processing industry, Amada offers a range of laser cutting machines and automation systems.

Competitive Advantage: Their extensive product portfolio and global presence enhance their competitiveness.

Mitsubishi Electric Corporation

Contribution: Mitsubishi Electric manufactures high-performance laser cutting machines known for their reliability and precision.

Competitive Advantage: Strong brand reputation and technological expertise contribute to their market success.

🛒 You can buy this market report at: https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=6894

Market Restraints

Despite its growth potential, the laser cutting machines market faces several challenges:

High Initial Costs

The upfront investment required for laser cutting machines can be substantial, which may deter small and medium-sized enterprises from adopting this technology.

Technical Complexity

Operating and maintaining laser cutting machines requires specialized knowledge and skills. The complexity of these machines can lead to challenges in training staff and ensuring optimal performance.

Competition from Alternative Cutting Technologies

Laser cutting faces competition from other cutting technologies, such as plasma and waterjet cutting. These alternatives may be preferred in certain applications due to cost or specific material requirements.

Market Segmentation Insights

The laser cutting machines market can be segmented based on various criteria:

Technology Type

CO2 Lasers: Widely used for cutting non-metal materials and some metals, known for their versatility.

Fiber Lasers: Increasingly popular for metal cutting due to their efficiency and speed.

Solid-State Lasers: Used for high-precision applications, particularly in the electronics industry.

Application

Metal Cutting: The largest segment, driven by demand from industries such as automotive and aerospace.

Non-Metal Cutting: Growing demand in industries like textiles and woodworking.

Medical Device Manufacturing: Increasing use of laser cutting in the production of medical devices due to precision requirements.

Geographic Regions

North America: A mature market with strong demand from the automotive and aerospace sectors.

Europe: Significant growth driven by advancements in manufacturing technologies and automation.

Asia-Pacific: Rapid industrialization and rising manufacturing activities present significant opportunities for market expansion.

To explore more market insights, visit us at: https://www.marketresearchfuture.com/reports/laser-cutting-machines-market-6894

Future Scope

The future of the laser cutting machines market looks promising, with several emerging trends and innovations on the horizon:

Emerging Trends

Industry 4.0 Integration: The adoption of smart manufacturing practices, including IoT and AI, will enhance the efficiency and capabilities of laser cutting machines.

Customization and Flexibility: Increasing demand for customized solutions will drive manufacturers to develop more adaptable laser cutting systems.

Innovations

Hybrid Laser Cutting Systems: The development of hybrid systems that combine different cutting technologies will provide greater versatility and efficiency.

Enhanced Software Solutions: Advances in software for design and operation will improve the user experience and operational efficiency of laser cutting machines.

Growth Opportunities

Emerging Markets: Growing manufacturing sectors in developing countries present significant opportunities for market expansion.

Sustainability Initiatives: The increasing focus on sustainable manufacturing practices will drive demand for efficient and eco-friendly cutting technologies.

The laser cutting machines market is poised for continued growth, driven by increasing demand from end-user industries, technological advancements, and the rise of automation. While challenges exist, the potential for innovation and market expansion presents exciting opportunities for manufacturers and investors alike.

More Related Reports from MRFR Library:

Industrial Valves Actuators Market: https://www.marketresearchfuture.com/reports/industrial-valves-actuators-market-23568

Reels And Spools Market: https://www.marketresearchfuture.com/reports/reels-spools-market-23575

Sand Blasting Machine Market: https://www.marketresearchfuture.com/reports/sand-blasting-machine-market-23508

Valves And Actuators Market: https://www.marketresearchfuture.com/reports/valves-actuators-market-23545

Powered Lawn Mower Market: https://www.marketresearchfuture.com/reports/powered-lawn-mower-market-23599

Market Research Future

Market Research Future

+ + 1 855-661-4441

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.