Inprentus Releases White Paper Highlighting Ultra Low Blaze Angle Grating Delivered to the European XFEL in Germany

Inprentus - The World Leader in Custom Blazed Mechnically-Ruled Diffraction Gratings

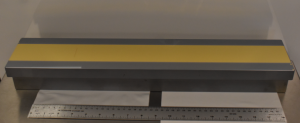

Unique 480-mm Long, Ultra-Low Blaze Angle Grating A Groundbreaking Achievement for Inprentus

The European XFEL, located in Hamburg, Germany, is the world's largest X-ray laser and is used for cutting-edge research in various fields including physics, chemistry, and biology. Inprentus was selected to provide diffraction gratings for the facility due to their reputation for producing high-quality, precision-engineered gratings. The white paper details the rigorous testing and evaluation process for the grating, with results corroborated by the customer's own metrology.

One of the key findings highlighted in the white paper is the exceptional simulated efficiency and accuracy of Inprentus' gratings, which provide significant performance improvements for the European XFEL beamline SASE3. The gratings' unique design of 0.1 degree blaze angle is the smallest blaze angle achieved in the world. It allows for better control of the high-energy, pulsed X-ray beam, resulting in more accurate and reliable data for researchers. This breakthrough technology has the potential to revolutionize the field of X-ray research and open up new possibilities for scientific discoveries.

"We are thrilled to share the results of our collaboration with the European XFEL in this white paper," said Dr. Peter Abbamonte, Founder and Chief Science Officer of Inprentus. "This is the largest mechanically ruled grating ever made for an FEL- the substrate is more than half a meter long. At the same time the groove characteristics are highly anisotropic; 20 micrometer pitch with a mere 30 nanometers depth. Our team works tirelessly to develop and deliver gratings that are considered impossible for others to make, using either mechanical ruling or any other competing technology. We are proud to be part of advancing scientific research and look forward to seeing the impact of our gratings on future discoveries."

The white paper is now available for download on Inprentus' website and serves as a testament to the company's commitment to innovation and excellence in diffraction grating technology. With this release, Inprentus continues to solidify its position as a scientific leader in the field and a trusted partner for cutting-edge research facilities around the world.

Cynthia Ottemann

Inprentus, Inc

+1 217-239-9862

email us here

Visit us on social media:

Facebook

X

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.