In-situ real-time monitoring revolutionized: computational imaging empowers laser material processing

USA, August 28, 2024 /EINPresswire.com/ -- Researchers in China have developed a dual-path snapshot compressive microscopy (DP-SCM) system that enables high-speed, high-resolution, and large field-of-view imaging for real-time monitoring of ultrafast laser material processing. This innovative system successfully observed the formation of nanograting structures from a snapshot compressed image, demonstrating its potential to revolutionize high-throughput imaging in laser processing applications.

A team of researchers led by Yuan Xin from Westlake University and Shi Liping from Xidian University has developed a novel computational imaging system designed to address the challenges of real-time monitoring in ultrafast laser material processing. The new system, known as Dual-Path Snapshot Compressive Microscopy (DP-SCM), represents a significant advancement in the field, offering unprecedented capabilities for high-speed, high-resolution imaging.

Traditional microscopy techniques often struggle to meet the demands of real-time monitoring in laser processing due to their limited imaging speed, restricted field of view, and insufficient resolution. These limitations, coupled with the vast amount of data generated during high-speed imaging, have made it difficult to achieve precise monitoring in dynamic, fast-changing scenarios.

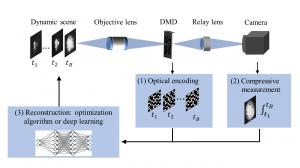

To overcome these challenges, the DP-SCM system employs a dual-path optical design that integrates both high-resolution and wide-field imaging capabilities. Each optical path uses snapshot compressive imaging technology, effectively breaking the bottleneck between imaging speed and data storage. This innovative approach allows the system to capture high-resolution images across a large field of view at unprecedented speeds.

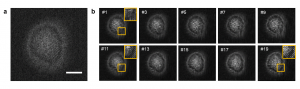

The DP-SCM system also incorporates advanced deep learning algorithms for image reconstruction, enabling the dynamic observation of micro- and nanostructures as they evolve over time. In experimental applications, the system successfully monitored the laser material processing and growth of nanogratings, providing crucial insights into the mechanisms underlying new material formation.

DOI

10.37188/lam.2024.029

Original Source URL

https://doi.org/10.37188/lam.2024.029

Funding information

This work was supported by the National Natural Science Foundation of China (62271414), Science Fund for Distinguished Young Scholars of Zhejiang Province (LR23F010001), Research Center for Industries of the Future (RCIF) at Westlake University. and Key Project of the Westlake Institute for Optoelectronics (Grant No. 2023GD007).

Lucy Wang

BioDesign Research

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.