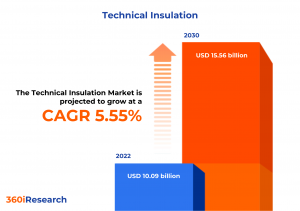

Technical Insulation Market worth $15.56 billion by 2030, growing at a CAGR of 5.55% - Exclusive Report by 360iResearch

The Global Technical Insulation Market to grow from USD 10.09 billion in 2022 to USD 15.56 billion by 2030, at a CAGR of 5.55%.

PUNE, MAHARASHTRA, INDIA , December 6, 2023 /EINPresswire.com/ -- The "Technical Insulation Market by Material (Cold-Flexible Insulation, Cold-Rigid Insulation, Hot Insulation), Application (Acoustic, Heating & Plumbing, HVAC), End-Use - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global Technical Insulation Market to grow from USD 10.09 billion in 2022 to USD 15.56 billion by 2030, at a CAGR of 5.55%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/technical-insulation?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

The technical insulation market encompasses materials and solutions designed to insulate equipment, processes, and systems that operate at high or low temperatures within various industrial sectors. These materials aim to enhance energy efficiency, control process temperatures and condensation control, and ensure personnel protection. Technical insulation applications range from HVAC systems, industrial processes, and refrigeration to automotive, aerospace, and oil & gas sectors. The scope of the market includes a wide array of insulating materials such as mineral wool, fiberglass, cellular glass, elastomeric foam, and various polymers and aerogels. Multiple factors influence the growth of the technical insulation market. Stringent regulations regarding energy efficiency and emissions in industrial processes drive the demand for advanced insulation technologies. The growing awareness of sustainable and energy-efficient buildings supports market expansion. Industrial growth, particularly in the manufacturing, energy, construction, and automotive sectors, directly correlates with the increasing use of technical insulation. However, several limitations and challenging factors could impede market growth. Fluctuations in the price and presence of raw materials can affect production costs and profitability. Compliance with diverse and evolving regulations across different regions represents a significant challenge. Labor shortages or lack of skilled workforce for the installation of technical insulation systems might also hinder market progress. Furthermore, the initial high investment required for insulating materials and systems can be a deterrent for small to medium-sized enterprises. The technical insulation market is ripe with opportunities stemming from the global push towards energy conservation and sustainability. The trend towards green buildings and retrofitting old infrastructure to improve energy efficiency present significant prospects. Innovations in lightweight and high-performance materials offer potential growth in aerospace and automotive applications.

Application: Growing application of technical insulation in HVAC systems

Technical insulation in acoustic applications is essential for reducing noise pollution and enhancing sound quality in various environments. It is commonly used in construction, automotive industries, and industrial machinery. Acoustic insulation materials are designed to absorb sound, dampen vibrations, and prevent noise transmission through walls, ceilings, and floors. In heating and plumbing, technical insulation is critical in supporting energy efficiency and preventing heat loss in systems such as hot water pipes, boilers, and heating ducts. Insulation materials designed for these applications are typically resistant to high temperatures and moisture, ensuring long-term performance and reducing the risk of corrosion under insulation. The use of insulation in HVAC systems improves thermal performance, ensuring that air maintains the desired temperature as it travels through ductwork. This minimizes energy losses, helping to achieve climate control goals and reduce operational costs. Insulation also helps prevent condensation and mold growth within the systems, thus contributing to healthier indoor air quality and prolonging the lifespan of the HVAC equipment. Technical insulation is utilized extensively in industrial process applications to control temperatures, protect equipment, and ensure worker safety. Whether it involves insulating pipes, tanks, boilers, or furnaces, the primary goal is to maintain process temperatures, maximize energy efficiency, and minimize heat loss. Insulation for refrigeration systems is focused on preventing heat gain and ensuring the effectiveness of cold chains in the commercial, industrial, and transportation sectors. Adequate technical insulation in refrigeration applications helps to maintain low temperatures, reduce energy consumption, and prevent system overload.

Material: Increasing preference for cold-rigid insulation in technical insulation

Materials used for cold-flexible insulation include elastomeric foams and polypropylene. Elastomeric foams, such as nitrile rubber, are widely appreciated for their excellent thermal conductivity, moisture resistance, and flexibility, making them ideal for preventing condensation and energy loss in refrigeration systems. They are also easy to install due to their flexibility and can fit snugly around irregular shapes. When it comes to cold-rigid insulation, materials such as extruded polystyrene (XPS), phenolic foam, and polyurethane & polyisocyanurate foam are prominently used. Extruded polystyrene is highly moisture-resistant and durable, suitable for below-grade insulation applications. Phenolic foam offers a high level of fire resistance with low smoke emission, making it a safer choice for various construction needs. Polyurethane and polyisocyanurate foams are recognized for their exceptional insulation properties, superb strength-to-weight ratios, and resistance to moisture, making them staples in cold storage and industrial refrigeration. Hot insulation materials such as calcium silicate and mineral wool are utilized to manage high-temperature environments. Calcium silicate is favored for its ability to handle temperatures up to 1200°F, comprising insulation for pipes and equipment in power generation and petrochemical industries where heat resistance is vital. Mineral wool, including rock and slag wool, offers excellent thermal insulation at high temperatures and sound absorption and fire resistance attributes.

End-Use: Expanding usage of technical insulation in commercial buildings

Technical insulation in commercial buildings is crucial for energy efficiency, safety, and comfort. It is employed in HVAC systems to reduce energy consumption by minimizing heat loss or gain. Insulation materials are installed in walls, roofs, and floors to enhance thermal performance, reducing operational energy costs. In the energy sector, technical insulation is used extensively in power plants, renewable energy systems, and oil and gas facilities. Its primary function is to maintain process temperatures, prevent heat loss, protect against corrosion under insulation (CUI), and ensure personnel protection. Therefore, the materials used must be high-performance, offering exceptional resistance to different forms of energy transfer. Industrial and OEM (Original Equipment Manufacturer) applications rely heavily on the benefits provided by technical insulation. Industries such as chemical, pharmaceutical, and food processing require precise temperature control and process efficiency facilitated by technical insulation. Insulation in these industries ensures that energy losses are minimized, processes are controlled, and emissions are reduced to comply with environmental regulations. The transportation sector, encompassing automotive, aerospace, marine, and rail industries, also benefits from using technical insulation. Insulation solutions in this sector are primarily geared towards enhancing energy efficiency, reducing weight, and improving passenger comfort by controlling temperature and noise. In automotive applications, insulation is vital for heat shielding and acoustic management. Compared to other sectors, commercial buildings often prioritize cost-effectiveness and regulatory adherence in their selection of insulation materials, and insulation in the energy sector is more focused on withstanding high temperatures and harsh conditions than the commercial or transportation segments.

Regional Insights:

In the Americas, the U.S., with its extensive industrial and energy sectors, robustly adopts technical insulation to enhance system efficiencies and comply with environmental regulations. Canada mirrors this trend with additional investments in sustainable insulation solutions due to its focus on environmental conservation. Both countries show a rising trend in customer preference for green and energy-efficient systems, reinforcing the demand for sustainable technical insulation products. The APAC region, including burgeoning economies such as China, Japan, and India, is observing rapid industrial growth and urbanization. There's a high demand for technical insulation in manufacturing, primarily to improve energy efficiency and meet regulatory standards. China ushers in patent filings, emphasizing innovative materials and applications in insulation technology. Japan offers a mature market with sophisticated consumer needs prioritizing high performance and advanced technology. With its expanding infrastructure, India shows a promising demand trajectory for technical insulation with increased investments in this sector. EU countries are at the forefront of implementing stringent regulations to achieve energy efficiency and reduce carbon emissions. This regulatory environment drives innovation and research, leading to a demand for advanced technical insulation solutions. The Middle East and Africa region, with its vast oil and gas reserves, significantly invests in technical insulation for its petrochemical industries. The Middle East is also diversifying its economies and emphasizing sustainability and energy-efficient construction, generating demand for technical insulation materials. In Africa, the growing construction industry, particularly in urban areas, drives the need for better insulation technologies, with several local and foreign investments supporting this growth.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the Technical Insulation Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the Technical Insulation Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the Technical Insulation Market, highlighting leading vendors and their innovative profiles. These include Armacell International S.A., Beijing Coowor Network Technology Co., Ltd., Cabot Corporation, Durkee(Wuhan) Insulation Material Co., Ltd., Insulcon Group, Johns Manville, Kingspan Group, Knauf Insulation d.o.o., L’ISOLANTE K-FLEX S.p.A., NMC sa, Owens Corning, Recticel NV, ROCKWOOL A/S, Saint-Gobain ISOVER, Temati group by IPCOM NV, and Unifrax I LLC.

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/technical-insulation?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the Technical Insulation Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Material, market is studied across Cold-Flexible Insulation, Cold-Rigid Insulation, and Hot Insulation. The Cold-Flexible Insulation is further studied across Elastomeric Foams and Polypropylene. The Cold-Rigid Insulation is further studied across Extruded Polystyrene, Phenolic Foam, and Polyurethane & Polyisocyanurate Foam. The Hot Insulation is further studied across Calcium Silicate and Mineral Wool. The Hot Insulation is projected to witness significant market share during forecast period.

Based on Application, market is studied across Acoustic, Heating & Plumbing, HVAC, Industrial Processes, and Refrigeration. The Heating & Plumbing is projected to witness significant market share during forecast period.

Based on End-Use, market is studied across Commercial Buildings, Energy, Industrial & OEM, and Transportation. The Transportation is projected to witness significant market share during forecast period.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Europe, Middle East & Africa commanded largest market share of 38.75% in 2022, followed by Asia-Pacific.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. Technical Insulation Market, by Material

7. Technical Insulation Market, by Application

8. Technical Insulation Market, by End-Use

9. Americas Technical Insulation Market

10. Asia-Pacific Technical Insulation Market

11. Europe, Middle East & Africa Technical Insulation Market

12. Competitive Landscape

13. Competitive Portfolio

14. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the Technical Insulation Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the Technical Insulation Market?

3. What is the competitive strategic window for opportunities in the Technical Insulation Market?

4. What are the technology trends and regulatory frameworks in the Technical Insulation Market?

5. What is the market share of the leading vendors in the Technical Insulation Market?

6. What modes and strategic moves are considered suitable for entering the Technical Insulation Market?

Read More @ https://www.360iresearch.com/library/intelligence/technical-insulation?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+1 530-264-8485

ketan@360iresearch.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.