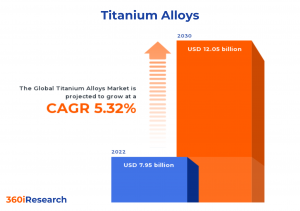

Titanium Alloys Market worth $12.05 billion by 2030, growing at a CAGR of 5.32% - Exclusive Report by 360iResearch

The Global Titanium Alloys Market to grow from USD 7.95 billion in 2022 to USD 12.05 billion by 2030, at a CAGR of 5.32%.

PUNE, MAHARASHTRA, INDIA , November 17, 2023 /EINPresswire.com/ -- The "Titanium Alloys Market by Microstructure (Alpha & Near-alpha Alloy, Alpha-Beta Alloy, Beta Alloy), End-User (Aerospace, Automotive & Shipbuilding, Chemical) - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global Titanium Alloys Market to grow from USD 7.95 billion in 2022 to USD 12.05 billion by 2030, at a CAGR of 5.32%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/titanium-alloys?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

Titanium alloys are combinations of titanium with other elements such as iron, aluminum, vanadium, molybdenum, cobalt, nickel, copper, and more. Titanium, the primary component of these alloys, is alloyed with small quantities of aluminum, vanadium, molybdenum, and other elements to enhance specific qualities. This results in various types of titanium alloys, each with unique mechanical and physical properties. These alloys, notable for their high tensile strength, lightweight, and corrosion resistance, find extensive applications across various sectors, including aerospace, automotive, medical, military, marine, and industrial. Titanium Alloys have increasingly been used across lightweight vehicles, aircraft structures, and medical implants due to the biocompatibility of these alloys. However, high production cost and machining of titanium alloy components is restarting the market growth. Apart from this, product innovation and technology developments in titanium alloys, along with alloy development for additive manufacturing processes or 3D printing, are expected to provide an opportunistic landscape for the market.

Microstructure: Proliferation of beta alloy due to their high strength, excellent cold formability, and fair weldability

Alpha and near-alpha Alloy alloys are utilized due to their extensive corrosion resistance and good mechanical properties at elevated temperatures. The Ti-6Al-4V alloy, recognized as Grade 5 titanium, is the most commonly used titanium alloy, attributed to its excellent combination of high strength, lightweight, and outstanding corrosion resistance. This alloy is primarily employed in the aerospace industry, medical industry for implants, automotive parts, and marine applications. Alpha-Beta Alloy has both alpha and beta phase structures, known for their versatility and balance of attributes. These alloys are identified for their moderate strengths and good formability at room temperatures. The Ti-3Al-2.5V is a Grade 9 titanium alloy commonly used in heat exchangers and hydraulic systems, as well as for aircraft tubing. Ti-6Al-2Sn-4Zr-6Mo alloy, also known as Ti-6246, is a high-strength alloy with good creep resistance up to 450°C and useful strength up to 350°C. Ti-6Al-4V ELI is an extra-low interstitial version of Ti-6Al-4V. This alloy is even more ductile with lower ultimate tensile strength and lower hardness, which allows better workability. It is widely used in the medical industry due to its biocompatibility, strength, and lightweight characteristics. Ti-6Al-7Nb, developed as a biomedical replacement for Ti-6Al-4V, depicts similar mechanical properties to Ti-6Al-4V, although considered safer for body implants and is broadly used in the medical industry. Beta alloys, such as Ti-15V-3Cr-3Al-3Sn, are distinguishable by their beta phase structure. This alloy displays high strength, toughness, and good fabrication and formability characteristics. It is often used in the aerospace industry both for structural components and for its ability to be readily formed into complex shapes at room temperature.

End-User: Significant use of titanium alloys in the automotive & shipbuilding industry

Automotive and shipbuilding industries use titanium alloys as they offer excellent corrosion resistance, high strength, and low density. The demand in these industries is driven by the ongoing trend towards light-weighting and reducing energy consumption in vehicles and ships. In the automotive sector, the alloy is utilized in components such as body panels, suspension systems, and exhausts, while in the shipping industry, it is often used in pumps, propellers, and hull structures. The aerospace industry is one of the prominent consumers of titanium alloys due to their durability, corrosion resistance, and strength-to-weight ratio. They are typically used in engine components, landing gears, and aerostructures. In the chemical industry, the role of titanium alloys comes into play in various apparatus, including heat exchangers, tanks, vessels, and pipes, due to their excellent corrosion resistance even in harsh chemical environments. In the power sector, titanium alloys are applied in nuclear reactors because they can withstand high temperatures and are resistant to radiation. Simultaneously, in desalination processes, titanium alloys are favored for their ability to withstand the corrosive effect of seawater. An increase in power generation capacities and the growing need for freshwater have further propelled the demand in these areas.

Regional Insights:

In the Americas region, demand for titanium alloys has been bolstered primarily by continuous innovation and an expansion of the defense and commercial aviation sectors. The aerospace industry makes up a significant portion of titanium alloy usage aligned with legislative policies promoting domestic manufacturing in this region, stimulating the market. In the EMEA region, titanium alloys are increasingly adopted across diverse high-growth sectors such as motorsports and high-performance auto manufacturing to offshore drilling and other marine applications. The European sub-region, home to several global automotive and aerospace leaders, is proving to be a major consumer. In the Middle East and Africa, rapid industrialization, infrastructural growth, and a robust oil and gas sector serve as positive indicators for the industry. APAC region showcases an opportunistic growth landscape for the market in the face of growing construction, automotive, and defense sectors. Increasing infrastructural development and the upswing in manufacturing industries in many developing economies are increasing the usage of titanium alloys with their property advantage.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the Titanium Alloys Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the Titanium Alloys Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the Titanium Alloys Market, highlighting leading vendors and their innovative profiles. These include Alloys International Inc., Altemp Alloys, Inc., AMETEK Inc., AMG ADVANCED METALLURGICAL GROUP N.V., Baoji Titanium Industry Co. Ltd, Böhler Edelstahl GmbH & Co KG, Corsnet Corporation, CRS Holdings, LLC by Carpenter Technology Corporation, Daido Steel Co., Ltd., Eramet Group, Haynes International, Inc., Hermith GmbH, KOBE STEEL, LTD., Kymera International, Nippon Steel Corporation, Outokumpu, Precision Castparts Corporation, Smiths Metal Centres Limited, Titanium Metals Corporation, Toho Titanium Co., Ltd, Tricor Metals, Inc., TWI Ltd., VSMPO-AVISMA Corporation, and Western Superconducting Technologies Co., Ltd.

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/titanium-alloys?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the Titanium Alloys Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Microstructure, market is studied across Alpha & Near-alpha Alloy, Alpha-Beta Alloy, and Beta Alloy. The Alpha & Near-alpha Alloy is further studied across Ti-6Al-4V. The Alpha-Beta Alloy is further studied across Ti-3Al-2.5V, Ti-6Al-2Sn-4Zr-6Mo, Ti-6Al-4V ELI, and Ti-6Al-7Nb. The Beta Alloy is further studied across Ti-15V-3Cr-3Al-3Sn. The Beta Alloy is projected to witness significant market share during forecast period.

Based on End-User, market is studied across Aerospace, Automotive & Shipbuilding, Chemical, and Power & Desalination. The Aerospace is projected to witness significant market share during forecast period.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Asia-Pacific commanded largest market share of 38.75% in 2022, followed by Europe, Middle East & Africa.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. Titanium Alloys Market, by Microstructure

7. Titanium Alloys Market, by End-User

8. Americas Titanium Alloys Market

9. Asia-Pacific Titanium Alloys Market

10. Europe, Middle East & Africa Titanium Alloys Market

11. Competitive Landscape

12. Competitive Portfolio

13. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the Titanium Alloys Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the Titanium Alloys Market?

3. What is the competitive strategic window for opportunities in the Titanium Alloys Market?

4. What are the technology trends and regulatory frameworks in the Titanium Alloys Market?

5. What is the market share of the leading vendors in the Titanium Alloys Market?

6. What modes and strategic moves are considered suitable for entering the Titanium Alloys Market?

Read More @ https://www.360iresearch.com/library/intelligence/titanium-alloys?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+ 1 530-264-8485

ketan@360iresearch.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.