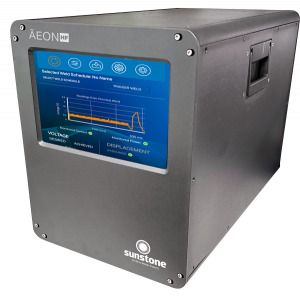

Sunstone’s Āeon HF Inverter Welder Increases Productivity with Advanced Duty Cycle, Completing More Welds in Less Time

Sunstone Engineering revealed the new Āeon HF inverter welder with an advanced duty cycle that empowers manufacturers to complete more welds in less time.

The Āeon HF is an inverter welder with full production, closed-loop feedback with a wide power range. Built around an innovative duty cycle design, the Āeon HF can deliver more welds within a set time period or, conversely, provide an elongated energy release for as long as three seconds, depending on the manufacturer’s needs. In either case, and with dual pulse capability, the operator can control weld energy in millisecond increments during the upslope, weld, and downslope phase of the energy release cycle. The Āeon HF is available in a 2500A model now with more powerful models in development.

Sunstone positions the Āeon HF as a modern inverter welder at a much lower price point with immediate availability. For its introduction and anticipated demand, Sunstone has units ready to ship.

“The Āeon HF is a significant welder for our customer for it will complete more successful welds within a give time period than the competition,” said Jonathan Young, CEO at Sunstone Welders. “The Āeon HF will outperform its nearest competitor three to one. Our advanced duty cycle design will draw the attention of every manufacturer because it will complete two welds by the time any other welder finishes just one. Packed with digital energy control and closed-loop feedback, the Āeon HF provides a cleaner, smoother weld, with much more energy.”

A large, digital touchscreen interface reduces operator training times while supporting exact energy control over every aspect of the weld. The result of innovative digital control is what Sunstone calls a “smoother” and cleaner weld. The operator can create a slow, soft increase in energy as opposed to a coarse punch, resulting in less splash and a more refined look.

“The Āeon HF is new inverter welding technology,” says Young. “It’s not your father’s inverter welder. Should you place the Āeon HF next to any other inverter welder you’ll be immediately struck by technology differences. With its advanced duty cycle, the Āeon HF is a game changer for many manufacturers who must boost production while meeting quality demands within a limited budget.”

Digital closed-loop feedback enables the Āeon HF to adapt to changes in resistance, dynamically monitoring the process 25,000 times per second. Should resistivity change during the weld, the Āeon HF will make whatever energy adjustments are required to meet set parameters. Automated alarms will alert the operator to discrepancies in expected results.

High-production facilities, automated production floors, or any manufacturing process wherein every weld must meet operator-defined specifications will benefit from integrating the Āeon HF into their production process. The automotive industry, medical device manufacturers, the aerospace market, battery manufacturers, and any other production process that requires high levels of process control over micro-level welds are target markets for this new welder and its advanced welding technology.

About Sunstone Engineering

Sunstone Engineering LLC designs, engineers, and manufactures high-tech micro welding and engraving solutions for many different industries. Sunstone welding technologies and solutions include laser, pulse arc, capacitive discharge, AC, linear DC, HF inverter, and hot bar reflow welding systems that are used in a variety of research and manufacturing fields and industries. Sunstone welders are used by Apple, NASA, MIT, GE, HP, Lockheed Martin, Boeing, multiple government and military agencies, and thousands of permanent jewelry artists. For more information visit www.sunstonewelders.com or call 801-658-0015.

Andy Jensen

Sunstone Engineering LLC

+1 385-999-5214

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Instagram

YouTube

Meet the All New Sunstone Aeon HF Inverter Welder

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.