Hellenic Cables Supplies Inter-Array Cables for Two US Offshore Wind Projects

Compared with the bottom fixed offshore wind power, floating offshore wind power to the sea extended a long distance, higher technical requirements, with better wind energy resources and greater technical potential.

According to BNEF data, in the 2021 global offshore wind turbine manufacturers ranking, Shanghai Electric, Ming Yang Intelligence, Goldwind and China Haizhuang occupy the top four positions in the global offshore wind turbine manufacturers.

Offshore wind power is a fast-growing solution. It meets the global demand for clean, renewable energy.

Hellenic Cables has finalized individual contracts with Ørsted and Eversource for two offshore wind projects in the United States.

NEW YORK, UNITED STATES, February 10, 2023 /EINPresswire.com/ -- Hellenic Cables Has Entered Into A Partnership With Ørsted And EversourceHellenic Cables has finalized individual contracts with Ørsted and Eversource for two offshore wind projects in the United States.

Under these contracts, Hellenic Cables will design, manufacture, test, and supply approximately 260 km of 66 kV XLPE insulated subsea inter-array cable and associated accessories for South Fork Wind and Revolution Wind in the northeastern U.S. Production will be phased through 2024.

Ørsted and Eversource are developing these projects which, when completed, will generate approximately 830 MW of clean energy, enough to power more than 420,000 homes. These offshore wind farms will make meaningful progress toward meeting national clean energy goals.

Alexis Alexiou, CEO of Hellenic Cables and Cenergy Holdings, commented: "This long-term partnership with Ørsted and Eversource demonstrates Hellenic Cables' commitment to the US offshore wind industry as a core part of our business and as a core part of our strategy for the future.

We are proud to be working with industry leaders on flagship projects that are transformative for the entire national energy industry."

Hellenic Cables reaffirms its leading role in developing the infrastructure critical to the U.S. and global energy transition.

Hellenic Cables' track record in the U.S. offshore wind industry includes Mayflower Wind in Massachusetts and Dominion's Coastal Virginia Offshore Wind, both of which provide 66 kV array cables.

Global Offshore Wind Power Development Status And Trend Analysis

I. Global Offshore Wind Power Market Overview

(1) New Installations Maintain Strong Growth Momentum

Thanks to technological advances and business model innovation, the wind power industry is growing rapidly, and GWEC's Global Wind Energy Report 2022 points out that in 2021, the global offshore wind power installed capacity of 21.1 GW, a twofold increase year-on-year, the proportion of new wind power installed in the world reached 22.5%, the largest increase in history.

By the end of 2021, the cumulative installed capacity of global offshore wind power reached 57 GW, up 58% year-on-year, and the share of offshore wind power in the global total installed wind power rose to 7%.

(2) Many Countries To Accelerate The Layout Of Offshore Wind Power Projects

At present, many governments have laid out offshore wind power as an important way to achieve energy security and transformation, as well as low-carbon goals, and set ambitious installed capacity targets. Recently, Europe, Asia, North America, and other major countries in the region to increase investment and construction of offshore wind power projects.

In Europe, this year, affected by the geopolitical situation, to ensure energy security, many countries adjusted energy policies, and increase the deployment of renewable energy, regional PV, and wind power installed demand to maintain a strong.

The UK released the "Energy Security Strategy" which proposed that by 2030 the UK installed offshore wind power capacity target from the previous 40 GW to 50 GW. Norway has announced plans to develop 30 GW of installed offshore wind capacity by 2040, which is almost equivalent to Norway's current total installed capacity.

The heads of government of Denmark, Germany, Belgium, and the Netherlands signed a joint declaration at the North Sea Offshore Wind Summit, committing to increase the four countries' installed offshore wind power capacity nearly tenfold from the current 16 GW to 150 GW by 2050. By 2030, the total installed offshore wind power capacity will reach 65 GW.

(3) The New Pattern Of Global Market Competition Has Formed

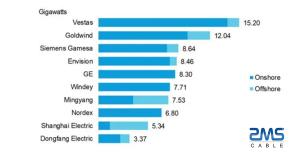

From the perspective of the global market competition pattern, according to the global ranking of wind turbine manufacturers in 2021 published by Bloomberg New Energy Finance (BNEF), Vestas (Vestas), Goldwind, and Siemens Gamesa (Siemens Gamesa) are the top three in the world, with a total installed capacity of 36% of the global market share.

Vision Energy ranked fourth in the world with a significant increase in exports, followed by General Electric (GE) in fifth place.

According to BNEF data, in the 2021 global ranking of offshore wind turbine manufacturers, Shanghai Electric, Ming Yang Intelligence, Goldwind, and China Haizhuang occupy the top four positions in the global offshore wind turbine manufacturers, with Shanghai Electric in the first place.

In terms of market share, the share of international wind turbine manufacturers in the Chinese market has been declining since 2010. According to BNEF data, in 2021 Siemens Gomersa's ranking slipped to sixth, replaced by the rise of Chinese complete machine manufacturers. In the past two years, China's "double carbon" goal led by the advantages of offshore wind power, and the speed of development.

Ⅱ. The Global Offshore Wind Power Development Trend Analysis

(1) To Large-Scale Continued To Move Forward

The average capacity of offshore wind turbines has continued to grow in recent years. In Europe, for example, the current average capacity of new offshore wind turbines in Europe from 7.2 MW in 2019 to 8.2 MW in 2020, with the increase in demand, wind turbine capacity more and more large-scale.

To date, the largest single capacity of foreign offshore wind turbines is 15 MW released by Vestas; the largest single capacity in China, but also the world's largest single capacity of offshore wind turbines for the Ming Yang Intelligent released 16 MW.

Future wind turbine capacity will continue to grow, and GWEC expects that the global average capacity of new offshore wind turbines will reach 11.5 MW in 2025.

Global offshore wind pioneer Henrik Stiesdal even believes that offshore wind turbine capacity will reach the milestone level of 20 MW by 2030.

Although larger turbines cost more than smaller models, these giant turbines can significantly reduce the cost of materials per unit capacity of a wind turbine, thus lowering the cost per unit capacity of wind turbine construction, while saving developers other costs such as foundations, cables, and installation.

According to Rystad Energy calculations, for 1 GW of offshore wind power projects, the use of 14 MW wind turbines will save $100 million in investment than the use of 10 MW wind turbines.

(2) To The Deep Sea, To Floating Wind Power

With the gradual development of offshore resources, offshore wind power projects continue to develop to the deep sea, due to the increased depth of the deep sea, the fixed support structure is more difficult, floating offshore wind power technology is considered by the industry as the "future of the main technology of offshore wind power development in the deep sea," has been explored in many countries and regions.

Comprehensive information statistics, 2021, the global floating offshore wind power installed 5.7 million kilowatts, and the cumulative total installed capacity has reached 12.14 million kilowatts. By the end of 2022, the global floating offshore wind power installed capacity is expected to reach 200~260 MW.

According to the European Wind Energy Association forecast, by the end of 2030, the global installed capacity of floating wind power will reach 15 million kilowatts, and a conservative estimate is that by 2050, the cost of floating units will fall by 38%.

As the world's largest offshore wind power market, China's deep-sea wind energy resources are very rich, and floating offshore wind power development prospects are very broad. Such as Hainan Province, excellent wind energy resources, and coastal waters above 100 meters in height wind speed between 7.5 to 9 meters per second, the medium and long-term offshore wind power development potential is expected to reach about 50 million kilowatts. China's "14th Five-Year Plan" renewable energy development plan put forward, strive to "14th Five-Year Plan" during the construction of China's first floating commercial offshore wind power projects, will also in the resources and construction conditions in the region to start several million-kilowatt offshore Wind power demonstration projects to start construction.

Compared to the bottom of the fixed offshore wind power, floating offshore wind power to the sea to extend a long distance, has higher technical requirements, with better wind energy resources and greater technical potential.

However, despite this, floating offshore wind power as a key emerging technology, in the commercialization of the application still faces high-cost challenges.

A report released by industry research firm DNV shows that the average cost of electricity for floating offshore wind farms is more than three times higher than for traditional fixed offshore wind.

Currently, in the floating offshore wind power construction cost composition, the highest proportion is the equipment and construction of the two links. In the future, reducing the cost of key components and processes will become a key driver of industry development.

Relevant data show that China's floating offshore wind power unit cost will be about 0.3 ~ 0.4 yuan before 2030, the same as the average feed-in tariff when China's floating offshore wind power is expected to formally enter the commercial development phase.

(3) Offshore Wind Power Hydrogen Production Will Become The Key Research And Development Direction Of The Industry

Green hydrogen produced by 100% renewable energy is becoming the focus of hydrogen energy development, and offshore wind power has higher stability and a larger scale than onshore wind power. It is a big advantage for electrolytic water hydrogen production, and the offshore wind power hydrogen production mode is receiving wide attention.

Globally, the Nordic countries, represented by the UK, Germany, the Netherlands, and Belgium, have laid out offshore wind power hydrogen production.

For example, the UK Dolphin project, which plans to use a stand-alone unit to produce hydrogen at a 4 GW floating wind farm in the UK North Sea, is scheduled to be commissioned in 2023 and to produce hydrogen on a 10 MW model by 2026.

The German AquaVentus offshore hydrogen project, located near Heligoland in the German North Sea, plans to establish a pilot project containing two 14 MW turbines by 2025, with an expected annual production of 1 million tons of green hydrogen by 2035.

The NortH2 project in the Netherlands plans to have its first turbines connected to the grid and produce hydrogen in 2027 and plans to have 4 GW of installed offshore wind power by 2030. The installed offshore wind power will exceed 10 GW by 2040, making it the largest offshore wind hydrogen project in the world.

In China, some local governments and enterprises are also accelerating the layout of offshore wind power hydrogen production projects. This year, Shanghai proposed in the Medium and Long-term Plan for the Development of Hydrogen Energy Industry in Shanghai (2022-2035) to carry out research on technologies related to hydrogen production from deep offshore wind power, and actively carry out the construction of demonstration projects in conjunction with the overall layout of Shanghai's deep offshore wind power.

Zhejiang Province in the renewable energy development in Zhejiang Province's "14 five" plan, will explore the new mode of offshore wind power base development, intensive to create "offshore wind power + ocean energy + energy storage + hydrogen production + marine pasture + onshore industrial base" demonstration project. Another relevant plan of other provinces also proposed to accelerate the layout of offshore wind power hydrogen production.

In the future, the richness of wind energy resources, the size of the project, and the progress of the transformation of the existing offshore gas transmission pipeline will affect the cost of offshore wind power hydrogen production.

BNEF expects that the median cost of hydrogen production from offshore wind power will drop to around US$7/kg in 2025 and below US$1/kg by 2050. By 2050, the cost of hydrogen production from offshore wind will be lower than that of hydrogen production from onshore wind.

(4) Offshore Wind Power Cable Types And Characteristics

The submarine cables used in the former offshore wind farms can be divided into array submarine cables and delivery submarine cables. The current offshore wind power project with submarine cable mainly includes the wind turbine connection cable (array cable, also known as collector cable) and the wind turbine grid-connected submarine cable (delivery cable, also known as the main submarine cable), the current 35kV array cable + 220kV delivery cable combination is the main.

Array cable

For array submarine cable, a 35kV AC collector solution is the conventional choice for offshore wind power. However, based on the demand for parity in offshore wind projects and the fact that offshore resources have been developed on a large scale, the trend has been towards larger individual units and projects far offshore, which is expected to develop towards 66kV AC submarine cables.

Due to the limitation of 35kV submarine cable thermal limit and flow-through capacity, the increase of single unit capacity makes the number of turbines that can be connected to a single array submarine cable decrease, still using 35kV AC collector solution will make the cable investment and the corresponding engineering costs and difficulties increase.

Taking 35kV, 400mm2 cross-section cable as an example, considering its thermal limit and through-current limit, the maximum active power transmission is usually allowed to be about 27MW, i.e. up to four 6MW wind turbines or three 8MW wind turbines can be connected.

The 66kV submarine cable with the same cross-section allows the transmission of 50MW of active power, which can connect eight 6MW units and six 8MW units. 66kV collector system cable number is reduced, cable investment and the corresponding cable laying project costs are reduced.

Transmission submarine cable

The AC power generated by the wind turbines is sent to the 110kV or 220kV offshore booster station through the array cable and then connected to the onshore centralized control center through the 220kV high-voltage AC cable.

As the scale of individual wind farms expands, and the demand for continuous development increases, some sea wind projects consider using 330kV or 500kV high-voltage AC submarine cables for power delivery due to economic considerations. The high-voltage AC submarine cable for power delivery.

At present, the mainstream voltage level of the sending submarine cable is 220kV, generally using a single three-core structure, with a transmission capacity of 180,000 to 350,000 kilowatts. As the scale of individual wind farms increases, higher-voltage AC transmission cables can be used.

III. Summary

Today, the scale of the global offshore wind power industry is growing rapidly, especially since the beginning of the year under the influence of geopolitical tensions, several European countries have accelerated the pace of new energy transition, significantly increasing the installed offshore wind power target, while also accelerating the project layout.

At the same time, technological advances in offshore wind power have reduced construction costs, opening up the market growth space. With the gradual development of offshore wind power to large-scale, deep sea direction, the support base of the unit also from fixed to floating type.

In the future, offshore wind power hydrogen production, other forms of energy or storage co-generation, and other new technology applications for industrial development opportunities, offshore wind power will also be combined with new economic models such as ocean pasture and seawater hydrogen production, to achieve comprehensive development and utilization of the marine economy.

The application of these innovative technologies and new models will contribute to the rich development of renewable energy and low-carbon transformation of energy.

ZMS Cable

ZMS Cable

+86 371 6782 9333

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

YouTube

Other

As an important means of contemporary international communication, submarine fiber optic cable is the main carrier of global information communication.

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.