Superior Seam Technology™ (SST) IMPROVES the Industry Benchmark Again and Adds an Extended Standoff Clip

OKLAHOMA CITY, OKLAHOMA, USA, May 24, 2022 /EINPresswire.com/ -- Building Research Systems, Inc (BRS) utilizing our proprietary Superior Seam Technology™ (SST) has once again advanced the industry benchmark for mechanically seamed architectural 2” x 16” vertical pan panel rib joinery wind uplift performance.

SST Innovation Yields Benchmark Uplift Results:

• The PC 216 roof system superior wind uplift performance improvement was accomplished using readily available MPS 1200 series clips (Movable Purlin Stabilizing).

• Superior wind uplift results exceed competitors WITHOUT the need for exterior mechanical seam clamps “roof wart” at clip locations which most depend upon to achieve their highest uplift values.

• Improved loading with unmatched wind uplift values using the long purlin stabilizing 4-hole base.

• Improved uplift values set the Panel Craft PC 216 apart from all other competitors without sacrificing the wider 5’-0” secondary framing attachment spacing capabilities of the roof system.

• Noticeable upgrade in seamer/seam due to new tooling design and setup for TripleLok® (stemmed from Continuous Product Improvement (CPI) for new PC fixed clip)

PanelCraft 216 – Allowable Wind Uplift Loads – All loads in Pounds per Square Foot

24 Gauge Material (Fy = 50ksi) with MPS 1200 Series

TripleLok Seam Test Report: C2518-1

Span: 2.0 - 1592 Test Ultimate Load: 358.4 | 1592 Design Load: 210.6

Span: 5.0 - 1592 Test Ultimate Load: 157.6 | 1592 Design Load: 92.0

QuadLok Seam Test Report: C2518-1

Span: 2.0 - 1592 Test Ultimate Load: 400.0 | 1592 Design Load: 235

Span: 5.0 - 1592 Test Ultimate Load: 167.5 | 1592 Design Load: 98.2

1. The above tabulated loads are generated from certified ASTM E-1592 testing using BRS’ MPS 1200 series clips and a BRS compliant seamer. These design loads are not valid with other clips or seamers.

2. Design loads contain a safety factor calculated per AISI.

3. These load capacities are for the panel itself. Frames, purlins, clips, fasteners, and all supports must be designed to resist all loads imposed by the panel.

4. Allowable wind uplift loads have not been increased by 33% as allowed by some codes when wind load controls.

5. This material is subject to change without notice. Contact Building Research Systems for most current values.

6. MPS 1200 Series Clips: MPS 1203, MPS 1213 and MPS 1220

• Note: These tested values apply to the 16” panel roof system and cannot be extrapolated for 18” wide panel performance.

SST™ Innovation Yields New Extended Standoff Clip:

• An addition of a 2” extended standoff MPS-1220 clip to the MPS 1200 series for improved energy option due to reduced compression of thicker fiberglass blanket systems over the purlins/bar joists which aids in meeting higher energy requirements.

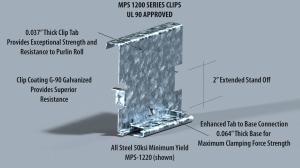

• All MPS 1200 series clip tabs are made from 0.037” thick (50ksi min. yield) material for exceptional strength and resistance to purlin roll forces.

• All MPS 1200 series clip bases are made from 0.064” thick (50 ksi min. yield) material for maximum clamping force strength to enhance the tab to base connection.

• All MPS 1200 series clip bases and tabs are G90 galvanized per ASTM A-653 for superior corrosion resistance.

• Can be utilized over screwed down metal over metal retrofit applications without an additional sub-framing system.

• All MPS 1200 series clips are UL 90 approved Construction. No’s 506, 506A, and 506B.

To find out more on BRS, visit www.brsusa.com or call (405) 607-8877 with any questions.

Cody Rodden

Building Research Systems, Inc.

+1 405-607-8877

crodden@brsusa.com

Visit us on social media:

Facebook

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.