Marktech Optoelectronics Announces Latest Lineup of Advanced Silicon Photodiode Photodetectors

Marktech's standard silicon photodiode are available through our distributors, Digikey Electronics and Mouser Electronics.

Marktech Optoelectronics, a leading manufacturer of UV to SWIR emitters & detectors announced their latest lineup of advanced silicon photodiode photodetectors.

LATHAM, NY, US, March 23, 2022 /EINPresswire.com/ -- Marktech Optoelectronics, Inc. (www.marktechopto.com)(Marktech), a privately-held and veteran-owned leading designer and manufacturer of standard and custom optoelectronics, including UV, visible, near-infrared (NIR), and short-wavelength infrared (SWIR) emitters, detectors, InP epi wafers, and other compound semiconductors, today announced their latest lineup of advanced silicon photodiode photodetectors.

Marktech’s silicon photodiode manufacturing facility Simi Valley, California has one the shortest delivery lead times in the photodetector industry for standard and custom photodiodes. Marktech can cross many competitor’s silicon photodiodes with a MADE IN THE USA product having specifications matching or exceeding the competitive specifications. After prototype approvals, custom photodiodes are typically delivered in a time frame of 6 to 10 weeks versus 6 to 8 months from other leading photodiode manufacturers. In addition, many standard silicon photodiodes can be delivered from our standard inventory in a few days through our distributor, Digikey Electronics and Mouser Electronics.

Silicon Photodiode (SiPDs)

Marktech’s lineup of advanced silicon photodiode detectors consist of several detector families or series based on their spectral sensitivity ranges:

• General Purpose (Series 8) – 350 to 1100nm spectral sensitivity

• UV Enhanced (Series 4) – 300 to 1100nm spectral sensitivity

• IR Enhanced Peak (Series 14) – 350 to 1100nm spectral sensitivity

• UV & IR Enhanced (Series 11) – 250 to 1100nm spectral sensitivity

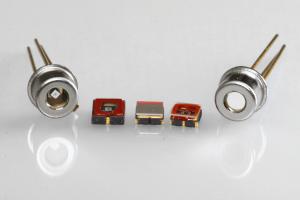

Silicon PIN photodiodes are available in various package types such as hermetically sealed metal cans (TO-5, TO-18, and TO-39), ceramic SAW packages, pigtail metal cans, and 3mm molded plastic through-hole (flat lens or dome ceramic). Custom packaging to OEM specifications is available as well.

Marktech’s Si photodiodes provide high sensitivity, low noise, excellent linearity, high quantum efficiency, and durability combined with an extended lifetime at a reasonable cost. Our UV Enhanced silicon photodiodes are ideal for monitoring the consistency of UV light sources for curing inks, resins, adhesives, sealants, and 3D printing stereolithography materials. In addition, Marktech’s IR emitters combined with our IR detectors (IR Peak silicon photodiodes) are the perfect solution in many industrial sensing applications such as proximity, linear position, time-of-flight (TOF) distance, and position sensors. Additional applications include optical power meters, color sensors, optical receivers, daylight detectors, oximeters, pulse monitors, particle analyzers, and smoke detectors.

Avalanche Photodiodes (APDs)

Marktech’s avalanche photodiodes (APDs) are perfect for high speed, short pulse, and low light level detection between 400 to 1100nm. They have optimal peak responses in the NIR band at 800nm or 905nm. Marktech APDs have low dark current, high internal gain at low bias voltage, and significantly higher sensitivities, especially in the near-infrared (NIR) spectral range, compared to standard photodiodes. They also have fast rise times as low as 300 ps, frequency response to 1 GHz, and a low breakdown voltage of 120V-200V. All Marktech APD products are also RoHS compliant.

Multiple Si APD customization options include operational voltage selection, wavelength-specific band-pass filtering, hybridization, and custom packaging. Custom package options include hermetically sealed TO metal cans, cost-effective SMD (LCC) types, proprietary seam welded ATLAS SMD, and other package types developed to OEM specifications.

Marktech silicon APDs can provide performance nearly equivalent to photomultipliers but in a more durable, reliable, and lower-cost semiconductor product. As a result, Marktech APDs can detect weaker light intensities in applications where higher bandwidth or internal gain may be required. Competitive photodetectors fall short due to higher preamplifier noise levels.

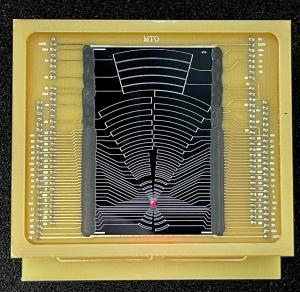

Silicon Photodiode Arrays (Si PDAs)

Silicon photodiode arrays have multiple photodiode elements fabricated on the same substrate and package. The photodiode arrays range from bi detectors (two segments), quad detectors (four elements), multiple element linear arrays, and complex multi-element area arrays.

Photodiode arrays are critical components in sensors and instruments for position sensing, laser alignment, spectroscopy, and particle analysis. For example, Marktech’s four-element photodiode arrays or quad detectors are perfect laser alignment applications. In addition, our linear photodiode arrays are ideal for position detection, spectrometry, refractometry, and other sensor or instrument applications.

Custom Photodetectors to OEM Specs

Marktech has extensive capabilities to design and manufacture custom photodetectors to OEM specifications from prototype to production volumes. The range of Marktech’s custom photodetector engineering and manufacturing include:

• Custom silicon photodiodes (Wafers, die, and packaged SiPDs)

o Custom photovoltaic silicon PIN photodiodes

o Custom silicon photoconductive PIN photodiodes

o Custom silicon avalanche photodiodes

• Custom InGaAs photodiodes

• Custom silicon and InGaAs photodiode arrays

• Custom photodetector packaging

• Photodetector co-packaged with additional components:

o Photodiodes combined with filters

o Photodiodes combined transimpedance amplifiers (TIAs), thermal electric coolers (TECs), or LED emitters

o Multiple photodiodes for broad band spectral range detection

• Custom photodetector assemblies (boards, flexible circuits, etc.)

Marktech’s newest manufacturing facility in Simi Valley, CA produces our advanced SiPDs. The California plant has a class 100 cleanroom and advanced packaging and assembly lines.

Marktech has a state-of-the-art optoelectronics laboratory for inspection and quality assurance testing of both detectors and emitters. Marktech routinely employs this capability to assist customers in troubleshooting problems with competitive SiPDs and developing OEM requirement specifications.

In addition, Marktech Optoelectronics can assemble endless combinations of multiple UV, visible, NIR, and SWIR emitters or LEDs photodiode detectors with the same package. Unique combinations of LED light sources and photodiode detectors are instrumental in developing sensors and instruments for detecting and quantifying specific chemicals, dissolved gases, and other biomarkers in process plant, clinical chemistry, wearable medical device, blood gas analysis, and point of care diagnostics.

Consult with Us Today About Your Design Project

Marktech Optoelectronics has vertically integrated capabilities to custom design and fabricate silicon photodetector and silicon photodiode array devices on wafers and then dice and package these photodiode chips with any required emitters, amplifiers, filters, and components for specific applications. This vertical integration allows Marktech to precisely control the performance and quality of the photodetectors and assemblies designed and manufactured for our customers.

If you have specific technical or application questions regarding your optoelectronics design project, then please contact our application engineers: info@marktechopto.com

Gary Kardys

Marktech Optoelectronics

+1 518-956-2980

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.