The GSO Series Gram Load Cells Offer Innovative Attachment Points Giving Engineers More Options

CAL-TEDS Plug & Play Smart Sensors Icon

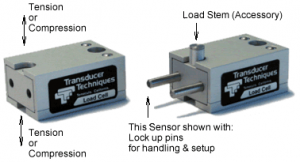

GSO Series Precision Gram Load Cell

These gram load cells feature a 6-32 tapped through hole sensing end that offers unlimited attachment possibilities.

TEMECULA, CALIFORNIA, UNITED STATES, February 23, 2021 /EINPresswire.com/ -- The GSO Series, Gram Load Cell, are available in ranges of 10, 25, 30, 50, 100, 150, 250, and 1000 grams full scale. The sensing end is a 6-32 tapped through hole providing unlimited attachment possibilities for tension and/or compression from top or bottom. A bonded foil strain gage full bridge provides a customer specified output of 1 or 2 mv/v. Combined accuracy of non-linearity and hysteresis is 0.1% of full scale or better. Suggested excitation is 10 VDC. They are supplied with a Load Cell Calibration Certificate traceable to N.I.S.T.https://www.transducertechniques.com

Transducer Techniques, established in 1979, designs and manufactures a complete line of load cells, torque sensors, special purpose transducers and related instrumentation. Transducer Techniques load cells are uniquely designed for weight and force measurement in such diversified applications as process control and factory automation. Other applications exist in numerous fields of science and industry for our load cells. All transducer sensing elements incorporate bonded foil strain gauges, wired in a full Wheatstone bridge configuration.

Technology

Load cells are electro-mechanical transducers that translate force or weight into voltage. This change in voltage produces a signal in the read-out instrumentation, a repeatable deflection or indication that can be calibrated directly in terms of the load applied to the load cell.

Construction

Construction of the load cell utilizes all the advantages of bonded foil strain gauges. Sealed within the load cell are sets of matched strain gauges bonded to a high strength element, machined to close tolerances. The strain gauges are electrically connected to form a balanced Wheatstone bridge and additional compensation resistors are added to the circuit for maintaining the accuracy of the bridge over a wide temperature range.

Operation

The principle of operation depends upon the deflection of the strain gauge filament, creating a change in its resistance, thereby unbalancing the bridge circuit. As a result, for a given input voltage, the output voltage of the bridge varies proportionally with the load and the change can be read on appropriate instrumentation.

Quality

When completed, each load cell is individually tested and calibrated. Each cell must meet or exceed rigid electrical and mechanical performance tests before it is released for service. Also, every cell is proof tested to its full rated capacity, and in most instances, to over its rated capacity.

Attributes

An important asset of our load cells is their extremely small deflection. The maximum deflection of standard cells does not exceed .012" at full load. This plus the fact that these load cells contain no moving parts opens unlimited application fields. The inherent compactness of the load cells minimizes installation problems.

The frequency response characteristics of our load cells are exceptionally good. The relatively low mass, and the small deflection under load, result in a high-frequency response which emphasizes the use of the load cells in many services where other transducers cannot perform.

Only strain gauges of the highest quality are installed and configured by technicians who have undergone our extensive training program targeting craftsmanship and attention to detail. To the end-user, this means a quality product. All Load Cells / Force Sensors and Torque Sensors are supplied with a Calibration Certificate traceable to NIST.

Customer Support

Transducer Techniques, LLC

+1 800-344-3965

email us here

Visit us on social media:

Facebook

Twitter

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.