Electro Scan Awarded 15km Pipeline Leak Detection By Major British Water Company

Electro Scan's award-winning machine intelligent leak detection awarded a 15km project in the United Kingdom.

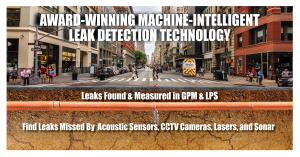

All leaks are located and measured in Gallons per Minute or Liters per Second, without relying on 'seeing' or 'hearing' defects at Joints, Customer Tap Locations, or Pipe Walls.

Award-Winning Machine-Intelligent Leak Detection Technology Selected Over Legacy Acoustic Sensors & CCTV Cameras to Pinpoint Leak Locations & Defect Flow Rates

"We are delighted to be awarded this important project to address Asset Management Plan (AMP) 7 requirements in the UK," stated Chuck Hansen, Chairman and Founder, Electro Scan Inc.

"We look forward to using our machine-intelligent technology to provide all UK framework managers unprecedented decision support in recommending rehabilitation priorities that make sense and provide proper QA/QC testing, prior to new construction approval," stated Brad Weston, Electro Scan UK Director.

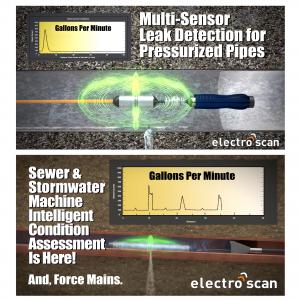

Already available in the United Kingdom and European Union, North American municipal and investor-owned utilities are welcome to register for the Virtual Smart Water Summit 2.0 (SWS) event to be held Thursday October 22, where the Company's senior management will announce the launch of its new award-winning Multi-Sensor Delta Probe for pressure pipe condition assessments in North America.

SWS 2.0 is free of charge to municipal and investor-owned utilities.

Smart Water Summit 2.0

Utility Registration Link

https://www.smartwatersummit.com/virtual-smart-water-summit-utility-registration

"Our Multi-Sensor Delta Probe is a game changer," according to Mike App, Vice President. "Working around the world, in all pipe depths, soil conditions, materials, and diameters up to 1800mm (72 inches), a single Electro Scan crew allows for daily inspection distances of up to 2.1 km (7,000 LF)."

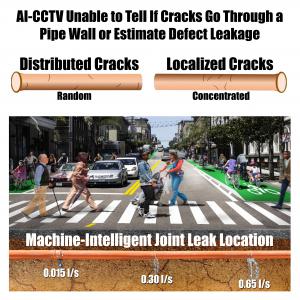

Industry veterans acknowledge that neither 'hearing' a leak with acoustic sensors or 'seeing' a leak with high resolution cameras have been able to deliver the accurate, unbiased, or unambiguous leak locations or relative severity expressed in industry standard rates of LPS or GPM.

While many water utilities are strategically deploying thousands of sensors throughout their network to identify 24x7 water pressure changes and event-based anomalies – identifying leak locations by size & severity has continued to be elusive and problematic – finding only a few and often low-quality leaks.

Representing an industry first, Electro Scan Inc. combines its patented Focused Electrode Leak Location (FELL), Closed-Circuit Television (CCTV), and Acoustic sensors, into a single Intelligent in-pipe electronic Internet of Things (IoT) platform, with the ability to survey up to 1km (3,000 LF), per insertion, to assess water mains, force mains, and sewer rising mains.

Unique to the pipe leak detection market, Electro Scan Inc. is the only known vendor able to locate leaks with 1 cm (3/8 inch) accuracy and estimates leakage rates for each defect in Liters per Second (LPS) or Gallons per Minute (GPM).

"CCTV cameras are clearly not effective in 'seeing' leaks or approving pipe lining as watertight," stated Weston.

"But, CCTV provides important navigational intelligence, such as seeing whether valves are open or closed, turbidity, air pockets, calcification, construction debris, and obstructions, including the location of illegal or non-revenue tap connections," continued Weston.

Representing a breakthrough, Electro Scan's low voltage conductivity technology, also known as Focused Electrode Leak Location (FELL), uses electric current emitted from an in-pipe tethered probe to locate and measure leakage rates.

Using scientific principles of Ohms' Law to document the amount of current escaping through an orifice or leak, combined with Torricelli's Law of leak measurement, Electro Scan provides unprecedented quantification and pinpoint leak locations, not available using traditional hydrostatic or air pressure testing.

With combined experience of over 3,000 pressurized pipe insertions, Electro Scan is well positioned to allow North American water utilities to correctly assess their water networks for Non-Revenue Water (NRW) and get same-day answers via the Company's Critical H20 Software-as-a-Service (SaaS) platform.

Previously it was hoped that Artificial Intelligence (AI) and Machine Learning (ML) would help extend the usefulness of CCTV video; however, visual inspection cannot distinguish differences between superficial cracks and cracks that go through a pipe wall, much less quantify leakage rates when a pipe is full of water.

Electro Scan's now well-established machine-intelligent (MI) technology overcomes longstanding inherent weaknesses in legacy pipe inspection methods.

The Company's 2020 Product Catalog may be downloaded free of charge.

A major benefit of Electro Scan, besides the accurate, fast, and reliable identification and quantification of pipe leaks, is the ability to identify leaks in new and existing Cured-In-Place (CIPP) lined pipes.

Originating in the UK in the 1970s, trenchless pipe rehabilitation – whereby existing pipes can be relined over pre-existing host pipes, thus eliminating the need to dig up streets – has become a global business reaching over $6 billion in annual revenue.

However, without having a valid quality control or quality assurance method, often relying on CCTV inspection to approve multi-million dollar projects, pipeline owners simply cannot obtain objective data about a liner's full-length 360-degree watertightness.

Even worse, customer tap reconnections that result from restoring mainline service to homes & businesses, are frequently found to create new or larger leaks that may exceed original leakage rates.

All testing is completed in accordance with AWWA M77 [WATER] and ASTM F2550 [SEWER].

The Company's leak detection project announced today is set to begin Monday, October 19 and scheduled to be completed by Christmas 2020.

Media, consulting engineers, contractors, industry associations, and academics, should contact the Company directly to arrange one-on-one (virtual) meetings to discuss specific worldwide project needs and case studies.

ABOUT ELECTRO SCAN (UK) LIMITED

Founded in 2014, Electro Scan UK is headquartered in Covent Garden, London, England (Company Number 9211607). While formerly partnered with WRc plc, a leading provider of international closed-circuit television (CCTV) visual inspection standards, the wholly-owned subsidiary of Electro Scan Inc. took over responsibility for sales, marketing, professional services, and project management for both sewer and water leak detection, including the its new Multi-Sensor Machine Intelligent Delta probe for pressurized water distribution mains and sewer rising mains. Electro Scan UK is Safe Contractor Approved.

ABOUT ELECTRO SCAN

Headquartered in Sacramento, Calif. and founded in 2011, the Company designs, develops, and markets proprietary pipe condition assessment equipment, delivers field services, and offers cloud-based data processing and reporting applications that automatically locate, measure, and report defects typically not found using legacy inspection methods. In 2020, the company was named to Government Technology’s esteemed GovTech 100 list for the second year in row. Electro Scan field crews and its authorized partners have been designated 'essential workers' adopting Coronavirus Health & Safety Standards, including appropriate use of Personal Protective Equipment (PPE) and Social Distancing standards, in accordance with state mandates and CDC recommendations.

#acoustic #acousticsensors #ai #aicctv #amp7 #astmf2550 #awwam77 #cctv #cipp #f2550 #faultycipp #fell #I&i #infiltration #IoT #leak #leakdetection #m77 #machinelearning #mscc #nassco #pacp #sewerai #smartwater #smartwatersummit2 #sws20 #SaaS #SWAN #trenchless #wsaa #wrc

Carissa Boudwin

Electro Scan Inc.

+1 916-779-0660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.