Electro Scan UK Rolls Out Best In Class Multi-Sensor Leak Detection for Pressurised Water Mains & Rising Sewer Mains

Electro Scan's Multi-Sensor Tethered Probe Allows British & European Water Companies to Accurately Locate and Measure Leaks in Pressurised Water Mains and Rising Sewer Mains.

Using listening sticks dating back over 100 years, modern survey crews also use highly sensitive acoustic devices that attempt to triangulate leak areas.

Locates Leaks With 1cm Accuracy & Reports Defect Severity in Liters per Second to Help Prioritise Water Main Repairs, Renewals, and Replacements

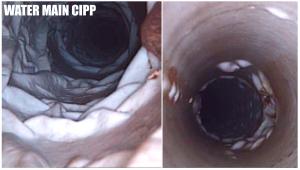

The new pipe inspection platform includes a traditional in-pipe tethered acoustic sensor to listen for leaks and a high-resolution closed-circuit television (CCTV) camera to observe internal pipe conditions and navigate obstructions in potable water mains ranging from 76-1500mm diameter.

The new solution also includes the company's flagship multi-patented low voltage conductivity sensor that is capable of 1 cm horizontal accuracy while also estimating leaks in liters per second (LPS) for each defect.

Electro Scan's multi-sensor approach saves on detection costs and allows water utilities to focus on higher value leak repairs to reduce overall leakage rates.

Electro Scan's low voltage conductivity technology was recently included in the American Water Works Association (AWWA) Water Supply Manual of Practice M77 "Condition Assessment of Water Mains" and was one of the few technologies listed to perform leak detection for Cured-In-Place Pipe (CIPP) or trenchless In-situ resin linings for water mains.

"We are delighted to offer such a ground breaking condition assessment and quality assurance solution for British & European water companies, especially given the aggressive reductions required by AMP7," stated Brad Weston, Director, Electro Scan (UK) Limited.

"In addition to being the first device able to measure pipe leaks in liters per second, our ability to determine the watertightness of new & rehabilitated water mains gives owners unprecedented CAPEX quality control, not previously available," commented Weston.

The company exclusively offers services directly to water companies or indirectly through authorized partners.

The announcement coincides with the company's recent invitation-only UK webinar attended by over 20 British and European water companies, with highlights of the webinar available for download.

"Water utilities are increasingly deploying low cost web-enabled sensors to transmit critical flow & pressure readings as part of developing an Internet of Things (IoT) digital twin of their physical network," stated Michael Condran, PE, Vice President, Electro Scan Inc.

"Combined with Automated Meter Reading (AMR) technologies, the industry still lacks critical condition data between the customer's meter and remote sensors to prepare a 'treasure map' that precisely identifies leak locations," stated Condran.

To expedite its adoption, Electro Scan's low voltage conductivity was incorporated into an existing industry-accepted water pipe insertion & retrieval solution – with over 4,000 successful potable water deployments worldwide, and approved for use in public water supplies.

The company's multi-sensor platform can also assess large diameter water transmission pipes and pressurised rising sewer mains, also known in the United States as force mains.

"For years, water utilities have been searching for alternatives to listening devices and data correlators to accurately locate leaks and quantify severities," stated Chuck Hansen, Managing Director, Electro Scan (UK) Limited. "In addition to prioritising leaks by severity, new technology was needed to reliably locate leaks in plastic pipes, used worldwide for new pipe installations."

In addition to his previous work founding one of the world's leading water & sewer enterprise asset management software companies in 1983, Hansen is the former Chair of the American Society for Testing and Materials (ASTM) Subcommittee F36.20 on Inspection and Renewal of Water and Wastewater Infrastructure, is a current member of the AWWA Water Distribution Condition Assessment Committee, and holds multiple U.S. and international patents for using conductivity to locate & quantify leaks.

Traditionally, acoustic leak surveys have been scheduled late at night. When noises from street traffic is low, water usage is reduced, and water pipe pressures are highest.

But, underground leaks are difficult to find using acoustic devices and even more challenging to quantify.

Unable to distinguish between large and small leaks, low value leaks are typically found and repaired that may result in only marginal improvement in asset life or improved water pressure.

In contrast, conductivity surveys can be scheduled anytime (day or night) as noise is not a factor.

Coupled with its unique ability to repeatably find & measure leaks in plastic pipes, low voltage conductivity supports a robust repair and quality assurance capability that can help minimise repair cycle times.

Adding low voltage conductivity to Electro Scan's multi-sensor platform is groundbreaking, since it is the first major inspection technology that is not dependent on having high water pressure to listen for leakage and can evaluate up to 1 kilometer of pipe during a single survey.

Thus, there is no need for multiple pipe insertions for different tests, and allows results to become immediately available.

Electro Scan's multi-sensor platform has little competition.

While another British company offers a conductivity-based solution, its inability to vary power outputs by pipe diameter or disperse multiple electric currents required to produce a focused defect pattern, prevents a 1 cm locational accuracy and liters per second leak quantification. Moreover, the lack of a streamlined field-to-office cloud-based reporting capability may contribute to longer lead-times impacting service restorations.

Still another technology utilises an untethered foam-encased acoustic sensor to assess larger diameter water mains; however, free-floating, uncontrolled devices may become caught or even lost, with false readings frequently caused when its device hits the wall as it travels through the pipe.

With testing results confirmed by numerous independent benchmark studies, including verification using COMSOL® Multiphysics® analysis, Electro Scan's multi-sensor probe handles a wide range of pipe materials, able to capture detailed geometry for corrosion & wall thickness analysis typically needed in assessing the remaining useful life of Asbestos Cement pipes.

Electro Scan technology was first introduced to the British market in 2013, working in collaboration with Wessex Water, to assess infiltration in sewerage and stormwater pipes.

ABOUT ELECTRO SCAN (UK) LIMITED

Founded in 2014 (Company Number: 9211607) with headquarters in London, England, Electro Scan field crews and its authorized partners have been designated 'essential workers' adopting Coronavirus Health & Safety Standards, including appropriate use of Personal Protective Equipment (PPE) and Social Distancing standards, in accordance with regulatory mandates and CDC recommendations. Electro Scan is also Safe Contractor Approved.

ABOUT ELECTRO SCAN INC.

Founded in 2011 and headquartered in Sacramento, California, USA, the company designs, develops, and markets proprietary pipe condition assessment equipment, delivers field services, and offers cloud-based data processing and reporting applications that automatically locate, measure, and report defects typically not found using legacy inspection methods. In 2020, the company was named to Government Technology’s esteemed GovTech 100 list for the second year in row.

Carissa Boudwin

Electro Scan Inc.

+1 916-779-0660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.