Electro Scan & Innovyze Partner to Deploy Game Changing End-to-End Condition Assessment & Rehabilitation QA/QC Solution

Seamless integration of Electro Scan FELL game-changing technology with Innovyze® InfoAsset Planner®.

Machine-Intelligent Solution Combined with Open Decision Support Platform to Enhance Stewardship of Capital Expenditures and Infrastructure Resiliency

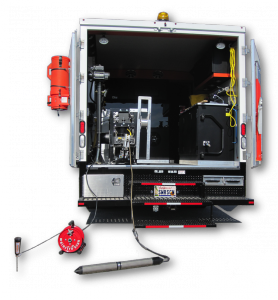

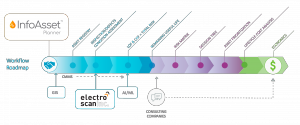

The integrated solution utilizes Electro Scan's SaaS-based cloud application and field-based Focused Electrode Leak Location (FELL) technology that is seamlessly accessed by the Innovyze® InfoAsset Planner® (IAP) for risk modeling and rehabilitation decision support.

“Some people might say that rehabilitation decisions are only as good as the condition assessment data they support,” stated Chuck Hansen, CEO and Founder, Electro Scan Inc.

"But, only Innovyze InfoAsset Planner can provide an easy to use, customizable, decision support engine that can deploy FELL data across the utility enterprise – including engineering, finance, operations, and maintenance – to make highly targeted capital investment decisions and certify pipelines as watertight,” Hansen added.

Innovyze, Inc. is a leading global provider of smart infrastructure modeling and simulation software solutions for government agencies, engineering consultants, and utilities, which was acquired by private equity firm EQT AB Group in May 2017.

Electro Scan Inc. is a privately-held 2020 GovTech 100 company founded in 2011 by software entrepreneur Chuck Hansen to enhance the stewardship of capital expenditures and infrastructure resiliency by proper assessment of old and newly installed pipelines.

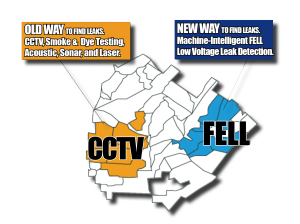

Prior to Electro Scan, municipal & investor-owned utilities were forced to assess the quality of repairs and pipeline rehabilitation using legacy-based Closed-Circuit Television (CCTV) cameras which have proven unreliable to provide consistent assessments and unable to perform watertightness testing.

Already deployed at utilities and used by engineering consulting firms, the separately licensed Innovyze-Electro Scan solution includes a web-based Application Programming Interface (API) for seamless data exchange.

A key advantage of the combined solution is the accuracy & repeatability of locating defects with the ability to assign defect flows in gallons per minute or liters per second in full-length sewer & water mains and at an individual customer's lateral connection, coupled with the industry's most user-friendly decision matrix.

In addition to significantly improving rehabilitation selection and prioritization, especially when using the Innovyze IAP Decision Matrix, Electro Scan’s ability to deliver post-rehabilitation testing for each individual constructed pipe while crews are still in the field, and before pay applications are approved, provides unprecedented quality control and asset stewardship to ensure pipes are delivered watertight.

The solution can easily & precisely assess, locate, and graphically display defects, including liner pinholes, found in post-rehabilitated Cured-In-Place Pipe (CIPP) within minutes of after curing.

“Our partnership with Electro Scan represents the beginning of using the Innovyze platform with best-in-class machine-intelligent technology to improve operational performance and CAPEX delivery," stated Erick Heath, Vice President, Global Partnerships, Innovyze, Inc.

“Users are already strengthening their decisions and we expect rehabilitation projects and day-to-day operations of sewer systems to be improved because of the real-time availability of reliable FELL inspection data in InfoAsset Planner,” stated Michael Condran, PE, Vice. President, Electro Scan Inc.

Uncontrolled flooding and sewer backups caused by excessive levels inflow and infiltration (I/I) in gravity sewers often results in significant homeowner damages, contaminated waterways, and costs to rate payers which cannot be easily found by using acoustic sensors or visual CCTV.

By using Electro Scan's FELL technology to precisely identify & quantify I/I within a utility’s network, infrastructure integrity is improved, maximizing system capacity and avoiding costly capital expenditures. FELL data integration into IAP marks a big step towards helping municipal agencies manage their I/I reduction programs much more effectively.

“Overreliance on any manual-based visual inspection technique creates a ‘Subjectivity Trap,’" stated Condran.

“Many of our customers have reported that using operator-biased, inconsistent, and unreliable CCTV inspection data has made meeting mandated regulatory I/I reductions a difficult task and staying within budgets nearly impossible. FELL technology is often referred to as 'the polygraph test for underground pipes' because of its unambiguous and repeatable results not found in any other legacy technologies on the market," added Condran.

“The first rule you learn about data is that bad data yields poor decisions,” stated Mike App, Vice President, NorthEast Region, Electro Scan Inc.

“Electro Scan’s FELL technology has been proven to significantly reduce the effects caused by relying on CCTV data and its inherent limitations. Our goal is to help agencies maximize I/I reduction at the lowest cost. By integrating machine-intelligent FELL technology into IAP’s powerful decision-making algorithm, municipalities gain immediate benefit,” added App.

Another drawback of using legacy techniques to accurately find leaks, noted by industry experts and academics, has been the inability to tell the difference between superficial cracks (that do not leak) and cracks that go through a pipe wall (that do leak).

Also, camera-based visual inspection is not able to ‘see’ up into each pipe's circular joint that have beveled edges obstructing full views, resulting in under-reporting of leaks at joints and service connections.

Recently, Hansen Analytics, LLC, an artificial intelligent (AI) data mining company, compared CCTV results on two sewer basins experiencing high rates of infiltration at a major metropolitan city operating under a multi-decade EPA consent decree. One basin had 202,393 linear feet of pipe, while the other basin had 204,4144 linear feet of pipe; yet, CCTV reporting by a national contractor using certified operators only identified 47 and 84 bad joints, respectively. In other words, visual CCTV cameras determined an almost watertight network of pipes.

At another major utility, 33,000 linear feet of pipe was evaluated, including 429 customer service laterals where homes are connected to the agency's sewer main. In this benchmark, certified CCTV operators identified five (5) defective customer tap locations, while Electro Scan's FELL technology identified 324 of 429 or seventy-five percent (75%) of connections with quantified leaks.

Add the lack of uniformity of visually assessing defects among certified operators, and it is easy to understand the challenge to reduce levels of infiltration based on CCTV results.

"Legacy CCTV inspection is still appropriate to locate service laterals and obstructions, including construction debris, fats, oil, grease, crossbores, and roots. However, its inability to locate or quantify leaks, especially in new or relined pipes, indicates that machine-intelligent FELL technology from Electro Scan is best suited to assess pipe conditions and rehabilitation effectiveness," stated Hansen.

FELL testing completed before and after rehabilitation is also able to provide a 'same-day' rehabilitation effectiveness reporting that has been successfully benchmarked with flow monitoring results that typically can take months or years to derive comparative changes in dry & wet weather flow reductions.

All pipes undergoing Electro Scan's machine-intelligent FELL testing is done in accordance with ASTM F2550 'Standard Practice for Locating Leaks in Sewer Pipes By Measuring the Variation of Electric Current Flow Through the Pipe Wall' and the American Water Works Association (AWWA) Manual of Water Supply Practices M77 'Condition Assessment of Water Mains.'

"Municipal agencies have spent enormous sums of money buying CCTV camera equipment and contracting CCTV services that we now know is not well-suited to locate or quantify leaks. We have always known that CCTV missed a substantial portion of infiltration, but didn’t know that CCTV cameras missed 80-100% of leaks until technology like Electro Scan quantified and compared the results,” added Hansen.

A leading subject matter expert on condition assessment and former Chair, ASTM Subcommittee F36.20 Committee on Inspection and Renewal of Water and Wastewater Infrastructure, Hansen developed the nation’s first widely used CCTV coding system adopted by nearly 1,000 agencies. In 1989, the City of Houston used Hansen’s CCTV codes and companion software to inspect all 5,000 miles of sanitary sewer with data collected by 250 CCTV trucks. At the time his company was sold in 2007, Hansen customers were storing over 1 million CCTV reports that included nearly 7 million defects.

“We look forward to working with Innovyze to transition clients to use FELL data in InfoAsset Planner to significantly improve decision making for their limited capital resources,” stated Hansen.

ABOUT ELECTRO SCAN

Electro Scan Inc., a leading supplier of machine-intelligent pipeline assessment products and services for the water & wastewater pipeline market. In 2020, the company. was named to Government Technology’s esteemed GovTech 100 list for the second year in row. Electro Scan Inc. develops proprietary pipe condition assessment equipment, delivers field services, and offers cloud-based data processing and reporting applications that automatically locate, measure, and report defects typically not found using legacy inspection methods.

ABOUT INNOVYZE

With over 35 years of heritage, Innovyze is a global leader in building innovative, industry-leading software for the water industry. Innovyze serves a growing customer base in over 50 countries including the majority of the largest UK, North American and Asian-Pacific cities, the foremost utilities on all major continents, ENR top-rated design firms, environmental and engineering consultancies, and refining plants that require optimized water and wastewater system management.

Carissa Boudwin

Electro Scan Inc.

+1 916-779-0660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.