Electro Scan Inc. Announces Major Software Release to Locate & Measure 'Pinhole' Leaks In Cured-In-Place Pipe (CIPP)

Widespread Use of Cured-In-Place Pipe (CIPP) for Trenchless Rehabilitation Results in Increase Demand for Early Warning QA/QC of Leaks, Pinholes, and Liner Permeability.

Roland Waniek, Managing Director, IKT, and Chuck Hansen, Chairman, Electro Scan Inc. at IKT - Institute for Underground Infrastructure in Gelsenkirchen, Germany, February 2019.

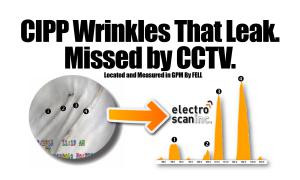

Wrinkles, folds, and ridges, typically accepted by CCTV and visual inspection, may register individual leaks resulting from improper curing.

Increased Demand for Trenchless Pipe Rehabilitation Prompts Cities & Consulting Engineers to Locate & Quantify Pinhole Leaks to Determine Liner Watertightness

The new release is available immediately and applies to all forms of CIPP liners, including Thermal (hot water), Steam, Ultraviolet, and Light-Emitting Diode (LED) cured liners.

Electro Scan's new software release is available for both imperial and metric customers, licensed to access the company's Critical Sewers® cloud application, with leaks quantified in either Gallons per Minute or Liters per Second.

"Electro Scan and Hansen Analytics have the ability to identify the major issues, where the money needs to be spent, and how to get the best return on investment for ratepayers," stated Mark McIntire, President, McIntire Management Group.

"Traditional pipe inspection methods have fallen short of testing and certifying new and rehabilitated pipes as watertight," stated Chuck Hansen, Chairman, Electro Scan Inc.

"We are pleased with the international acceptance of our patented Focused Electrode Leak Location (FELL) technology to deliver unbiased, unambiguous, and repeatable results to fix our crumbling infrastructure," stated Hansen.

Evaluating CIPP liners since 2014 when it completed an assessment for James City Service Authority, Virginia, Electro Scan has gone on to complete over a thousand CIPP evaluations, including review of over 30 CIPP suppliers and contractors.

Working with its UK partner on a CIPP research project for German-based IKT made Electro Scan management realize the importance of quantify leaks, including pinholes.

Recommended CIPP liner repair, replacement, or removal alternatives can be quite different given the location, frequency, and watertightness of all defects that leak.

It is also important to locate liner defects as soon as possible after installation and curing, while crews are still mobilized in the field.

“Traditional inspection methods including Acoustic and Closed-Circuit Television (CCTV) inspection are unable to identify or measure leaks," stated Mike App, Vice President, Electro Scan Inc.

"Instead, FELL's machine-intelligent solution can bring needed accuracy and simplified reporting without the need for third-party data interpretation to determine when a liner is watertight," stated App.

Electro Scan Inc. offers the only technology that is in compliance with ASTM F2550 and AWWA M77 standards for testing the watertightness of CIPP liners.

It is estimated that North American investor-owned and municipal utilities spend over $5 billion annually on trenchless rehabilitation products and services.

Recently, Electro Scan announced a 30-mile condition assessment project for Hillsborough County, Florida, and a 22-mile condition assessment project for the City of Kansas City, Missouri's Smart Sewer program.

While both the Hillsborough County and Kansas City projects are designed to evaluate existing sewer mains, prior to rehabilitation, a large number of previously lined CIPP will also be evaluated for watertightness.

In addition to designing and marketing equipment that utilities can purchase and add to existing CCTV trucks or vans, Electro Scan also licenses its patented FELL technology to authorized contractors offered on a Technology-as-a-Service (TaaS) basis.

Once FELL surveys are completed, data can be transmitted, stored, and processed in its proprietary Critical Sewers® cloud application, independently managed by Hansen Analytics LLC, with licensing available on a Software-as-a-Service (SaaS) basis.

Separately, Hansen Analytics LLC, allows customers to upload all their pipeline condition assessment data, including but not limited to Acoustic, CCTV, Dye Test, Laser, Pressure Testing, Smoke Testing, and Sonar data that can easily be ported to Geographic Information Systems (GIS), Hydraulic Models, and Management Dashboards.

Electro Scan's new software release also locates and measures small defects in plastic pipe, including High Density Polyethylene, Polyvinyl Chloride, Polyethylene, and other plastic pipes.

FELL testing is recommended to certify both gravity and pressurized pipelines for watertightness.

ABOUT ELECTRO SCAN INC.

Founded in 2011, the company designs, markets, and supports machine-intelligent products & services for pipe condition assessment, environmental compliance monitoring, and measuring rehabilitation effectiveness. In 2019, the company was named by BlueTech Research as a ’Top 15 Water Technologies to Watch’; Fast Company’s ‘World’s Most Innovative Companies’; and, e.Republic Government Technology ‘GovTech100.’

#bluetech

#cctv

#cipp

#consentdecree

#electroscan

#epa

#fastcompany

#fell

#govtech100

#infiltration

#keepinnovyzing

#leakdetection

#leaks

#pokeandhope

#technologycapital

Carissa Boudwin

Electro Scan Inc.

+1 916-779-0660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.