First Quarter of 2019 Sees Upsurge in Interest in HPS Automated Liquid Transfer Technology

Increase in Automated Liquid Transfer Solutions Driven by Safety, Efficiency and Productivity - HPS

NOTTINGHAM, NOTTINGHAMSHIRE, UNITED KINGDOM, May 22, 2019 /EINPresswire.com/ -- HPS Product Recovery Solutions, the leading specialists in process pigging and liquid transfer solutions, has reported a steep interest in the first quarter of 2019 for its Automatrix systems.

The company, which is headquartered in Nottingham, UK, says that because safety, efficiency and productivity are high priorities for the process industries, an increasing number of companies are turning to automated liquid transfer solutions such as its ‘Automatrix’.

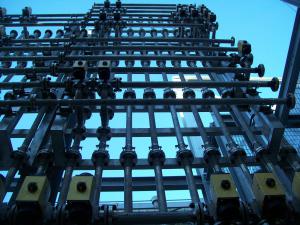

Also known as the ‘Piggable Automatic Liquid Transfer Matrix System’, the HPS Automatrix is a fully automated valve matrix that’s suited to companies that transfer liquids from multiple sources to multiple destinations.

It’s in wide use in a diverse range of hygienic and industrial applications, including, but not exclusive to, paint and coatings, wine transfer, foods and bottling and dairy.

As well as increasing safety, efficiency and productivity, the Automatrix reduces the chances of connection errors. It also cuts the amount of pipework required, frees up space, and reduces the number of hoses needed.

And because the Automatrix incorporates product recovery (‘pigging’) technology, most of the residual liquid is recovered rather than going to waste (which can be the case with other liquid transfer systems). This increases yields, reduces water consumption, speeds up changeover times while lowering contamination risks and cutting waste disposal costs.

Gilbert Murphy, CEO of HPS Product Recovery Solutions, commented,

“Not only are companies that process liquids demanding processing equipment that improves safety, but they need this equipment to enhance their productivity and efficiency of their operations too. That’s why the Automatrix is a perfect solution and one of the key reasons its surged in popularity in recent years and this year in particular”.

“The Automatrix offers many benefits to companies transferring liquids with multiple sources and multiple destinations. What makes the Automatrix so special is that, unlike other products on the market, it has close-fitting valve configurations with minimal dead-space or pockets. So, this means the HPS pig can easily travel through it and recover nearly all the product”.

The Automatrix is usually bespoke and designed specifically around the requirements and processes of each customer. It can be designed in a range of configurations, including vertical, horizontal and as a portable skid.

HPS can incorporate the Automatrix into existing plants, as well as part of new installations. Gilbert continued,

“The flexible design of the Automatrix means it can easily be installed in manufacturing plants with very little downtime. Once installed, the Automatrix doesn’t need much looking after and is straightforward to use and maintain”.

"Its flexibility enables it to accommodate significant expansion in sources and destinations to meet future production needs. With horizontal configurations, this is practically limitless. With vertical configurations, only height restricts more lines being added”.

The Automatrix is in use by a wide variety of organisations throughout the world. It's expected that interest in the Automatrix will continue the upward trend during the second quarter of 2019 as even more organisations that process liquids look to improve safety and drive efficiency and productivity improvements.

Kim Rousell

HPS Product Recovery Solutions

+44 115 925 4700

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.