[Free Webinar] - Chemical Processing Engineering Industry - "Mixing Tank – Scale up Your Mixing Process" March 01, 2017

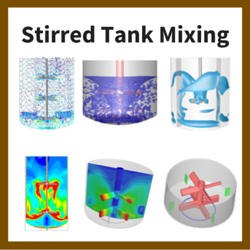

mixing in stirred tank

Chemists and Chemical Engineers are focused on transforming raw materials into value added products. Stirred tank is one of the widely used unit operation for these transformations. Recipes are developed in the lab and then transferred to the production units. Such differences can make scale-up from the laboratory or pilot plant challenging. Process Engineers will need to fit this recipe in an existing tank; and depending on the production site, the available configurations would change. So the same product will need to be made in tanks of various configurations and this can be challenging. Various methods are available to evolve the design/operating condition for the production scale vessel.

This webinar will provide insights on various scale-up rules available for different batch mixing processes. Methods to scale-up batch mixing processes from lab to pilot plant to production and how to apply the available scale-up methods for successful scale-ups. Examples demonstrating the successful use of mixing scale-up techniques for stirred tanks in the Pharmaceutical, Bio-Pharma, Bio-Technology and Chemical (specialty, fine and consumer) industries will be presented.

For more information and to register for this webinar visit http://mixit.tridiagonal.com/mixing-tank-scale-up-methods-webinar

About Tridiagonal Solutions Inc

Tridiagonal Solutions Inc is an advanced engineering solutions provider with expertise in process performance enhancement and product development solutions for industrial clients worldwide. Their portfolio includes process engineering, CFD, EFD, DEM services and chemical mixing simulation products. Tridiagonal Solutions caters to the Chemical and Process, Oil and Gas, Consumer goods, Food, Electronics, Power Generation and Healthcare Industries.

MixIT Team

Tridiagonal Solutions Inc

+1 (210) 858-6192

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.