Why Choose Permanent ESD Solutions Over ESD Mats

Frustrated with ESD mats? We get that, so we created a permanent solution. Read more to find out why our clients prefer ESD workbench solutions over ESD mats.

Formaspace has lots of experiencing providing ESD compliant workbench solutions to very well-known manufacturing companies, including Intel, Dell Computer, Gulfstream Aerospace and many more.

AUSTIN, TEXAS, UNITED STATES, July 7, 2016 /EINPresswire.com/ -- In the semiconductor manufacture and repair industry, providing a reliable ESD protected area (EPA) to assemble, calibrate, repair and ship ESD sensitive components is crucial. Static discharges as low as 10V can damage sensitive components without being noticed; damaged components may fail over time leading to product failure, costly field repairs, recalls and unhappy customers. — Mike Triche - Sales Manager at Formaspace

Over the past 25 years, we have witnessed the greatest technological expanse ever, yet how many production facilities are still working on those ESD mats from the early 1990s?

Not convinced? Here are three reasons you should consider ESD solutions from Formaspace.

1. Formaspace offers custom, built-in ESD bench solutions

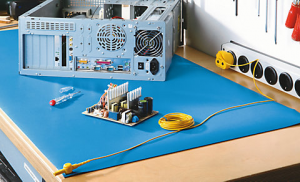

Here at Formaspace we provide ESD solutions that are aesthetically pleasing to the eye, easy to maintain, durable and ANSI ESD S20.20 compliant.

Once you’ve experienced working with a workbench with ESD built-in, you’ll never want to go back to portable ESD Mats again.

Whether you’re looking for a quick, cost effective solution or a complex, fully custom EPA, our team here at Formaspace will help you build a solution that will fit your needs.

2. Portable ESD Mats are problematic and costly to replace.

Most of the ESD damage our clients experience in the semiconductor manufacture and repair industry is caused by a simple human error. Employees inspecting ESD sensitive components may become distracted and set the component down on a non-ESD protected area.

If ESD sensitive components are set down upon non-ESD protected surfaces, the potential for ESD damage rises considerably. Sometimes the damage is catastrophic — rendering the component immediately inoperable. However, in many cases, there can be latent damage that goes undetected in the factory — leading to costly product failure in the field.

Portable ESD mats are risky because they are usually cut to fit a certain portion of the work surface due to the difficulty of moving heavy equipment across the mats. This leaves a significant portion of the workbench’s ‘real estate’ exposed.

Portable ESD mats have other problems as well. Even with a proper cleaning schedule, ESD mats can still retain oils and dirt from employee’s skin and clothing; over time this leads to degradation of the protective surface properties of portable ESD mats.

ESD mats can also become damaged by many day-to-day operations. Common activities that can damage mats include: dragging heavy equipment over the surface, cutting directly on the surface, soldering directly on the surface and using heat guns directly over the surface, to name just a few. Working with glue, solvents, aerosols or other chemicals can also quickly damage ESD mats.

As a result, some of our clients have been replacing their ESD mats on a bi-yearly basis; at $250+ each this becomes very costly in a hurry.

3. It’s easy to replace your portable ESD Mats with a permanent ESD bench solution.

It’s time for a change. Formaspace can provide a permanent solution to all your ESD needs.

Formaspace ESD workbenches are laminated with a dissipative, high-pressure laminate (HPL); we also offer a dual-layer HPL that contains a carbon layer under the dissipative layer for use with continuous ESD monitoring systems.

Both of these HPL types meet NEMA LD 3-2005 standards for appearance, impact resistance, wear resistance, temperature resistance, water resistance, steam resistance and chemical resistance.

When using either of our HPL surfaces, the entire work surface becomes ESD protected, allowing employees to have the freedom of using the entire work surface to perform their daily activities.

And HPL surfaces are much more durable and practical than portable ESD mats. For example, test equipment can be moved around easily over HPL surfaces without scratching, something that’s just not possible with portable ESD mats.

Cleanup is very simple too. The bench surfaces are washable. Once the area is cleaned, all it takes is a simple wipe with an approved ESD work surface cleaner, and the work surface is ready for the next task.

Get in touch with us to learn more.

Formaspace has lots of experiencing providing ESD compliant workbench solutions to very well-known manufacturing companies, including Intel, Dell Computer, Gulfstream Aerospace and many more.

Why not drop an email to one of our Formaspace Design Consultants today? They’ll be happy to answer your questions and give you fresh ideas on how to work more productively.

Mehmet Atesoglu

Formaspace

8002511505

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.