Flottweg Features Sorticanter at Plastics Recycling Conference

Visit Booth #939 to see how Flottweg decanters provide an environmental solution to the plastics recycling industry.

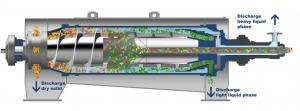

GRAPEVINE, TEXAS, UNITED STATES, March 12, 2024 /EINPresswire.com/ -- With an increasing focus on eco-friendly technology and recycling, new and innovative solutions like the Flottweg Sorticanter® provide powerful centrifuge equipment without sacrificing environmental protection.

To learn more about Flottweg’s advanced separation technology for the plastics recycling industry, visit booth #939 at the Plastics Recycling Conference in Grapevine, TX March 25 – 27, 2024.

“Naturally occurring raw materials such as plants, coal, natural gas, and crude oil are the basic materials for the production of plastics,” explains subject matter expert Lee Betkowski of Flottweg. “These raw materials cannot be recovered through processing in chemical steps. The recycling of plastics is therefore an issue for every environmentally conscious person. The Sorticanter® makes it possible to make a contribution to environmental protection in accordance with the principles of ecology and economy.”

The centrifugal force generated enables the Sorticanter® to separate different types of plastic from each other. This enables operators to achieve the highest possible purity of plastics. Collecting and recycling plastics also reduces disposal costs and mountains of waste.

Flottweg Sorticanter® has been processing a wide variety of plastics since 1995. The Sorticanter® has impressing performance and exceptional quality and durability. The high-quality materials of Flottweg’s Sorticanter® reduce the expenditure for servicing and maintenance measures.

“The machine is easy to control and maintain, and worn parts are easy to replace,” Betkowski says. “This reduces the workload on the operating personnel. The operating parameters can be clearly controlled via a user interface. As the Sorticanter—like other decanter centrifuges—forms a closed system, the operating personnel's exposure to unpleasant odors is minimal.”

This event is where the plastics recycling industry meets to connect with more than 2,500 leaders from plastic processors, recycled resin buyers and sellers, and other key stakeholders.

Attendees will learn the latest about the recycled plastic markets and trends with a three-day, info-packed agenda curated by industry experts.Experience the industry’s most lively trade show hall, featuring more than 250 processors, compounders, equipment vendors and others, including Flottweg.

Event attendees will also hear directly from global brands and get up to speed on the most important developments in an evolving sector.

The Plastics Recycling Conference event annually brings together top executives and decision-makers from plastics processors, converters, global brands, resin manufacturers, government agencies, trade groups, and other key sector categories.

Flottweg was present from the beginning, when plastic recycling in Germany went mainstream in the 1990s. Since then, the company has been delivering complete systems for wet-mechanical sorting and washing of plastic mixtures. Learn from our experience and knowledge during engineering design, the selection of components, or in the specification of measurement and control systems. Flottweg also boasts a well-equipped test facility with an experienced team for system design via small commercial-scale testing in order to provide the best system tech- nology for your application.

Daniel Lakovic

Flottweg Separation Technology

+1 (937) 554-2660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

YouTube