Sunstone Welders Introduces the Wave AC, the Industry’s First Digitally Controlled AC Welder

Sunstone Welders proudly introduces the Sunstone Wave AC, the industry’s first AC welder controlled by a digital touchscreen interface.

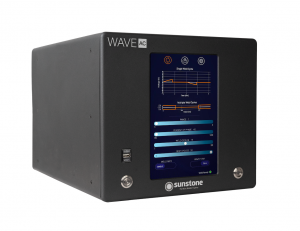

The Wave AC introduces unprecedented levels of control and visualization to the welding process. With a 10-inch color touchscreen, operators can now experience welding parameters in real-time as a dynamic waveform. Enabling operators with this level of insight enables them to fine-tune settings with unmatched precision, leading to superior weld quality.

Jonathan Young, CEO of Sunstone Welders says, "The Wave AC is a first in the industry and another example of our commitment to provide best-in-class welding solutions by providing our customers with digital control over every aspect of the weld. The Wave AC is more than just a capable welder; it's a promise of efficiency, precision, and excellence in every weld. We invite medical device, battery, and automotive industries to experience highly advanced welding with the Sunstone Wave AC."

Specifically designed for the 21st century, the Wave AC’s cutting-edge electronics significantly enhance energy precision, resulting in superior welding outcomes. The Wave AC boasts a 10-inch color touchscreen display and a newly engineered transformer with advanced circuitry. The large touchscreen display offers unprecedented visualization of welding parameters in a waveform, updating dynamically as operators make adjustments, allowing real-time insight into energy delivery to the workpiece. Save/Load weld settings add a layer of convenience, allowing operators to optimize settings for specific jobs and effortlessly reload them as needed.

The Wave AC simplifies parameter customization, making it an exceptional solution for continuous seam welding, foil welding, pouch cell welding, mesh or screen welding, hermetic sealing, and filter production in semi-automated manufacturing environments.

“You only have to place the Wave AC next to any other AC welder to see it is a standout welder,” says Young. “Manufacturers will be drawn to the Wave AC’s modern, digital features, but they’ll be more impressed by how wonderfully well the Wave AC performs.”

Andy Jensen

Sunstone Engineering LLC

+1 801-319-4157

email us here

Visit us on social media:

Facebook

Twitter

Instagram

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.