King Machine Elevates Tire Mold Manufacturing in the USA with the Acquisition of AddUp’s FormUp 350

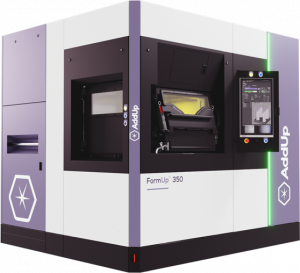

King Machine, the world’s fastest tire mold manufacturer, proudly announces the acquisition of an AddUp FormUp 350 Powder Bed Fusion (PBF) machine.

King Machine is the largest independent tire mold company in North America with all mold manufacturing conducted at their advanced manufacturing facility in Charlotte, NC, complemented by 11 additional locations dedicated to mold repair and servicing. Their presence across North America allows them to serve their expansive network of tire OEMs efficiently, ensuring prompt response times and unwavering support for their valued customers.

Recognizing the potential of additive manufacturing, King Machine has embarked on a journey to integrate this innovative technology into the production of tire molds. By utilizing AddUp’s additive technology, King Machine has achieved an unprecedented level of precision and quality in their tire sipes which was not possible using the manufacturing technologies deployed by their current supplier.

Previously, the manufacturing of the tire sipe mold component was outsourced overseas, leading to supply chain inefficiencies and high costs for King Machine. To address these issues and remain competitive in the U.S. market, vertical integration was a necessary step. By bringing the manufacturing process in-house with additive technology, King Machine has improved profitability, enhanced sustainability, and elevated their capabilities, enabling their customers to set a new standard in quality and performance in servicing their clients. This strategic move also aligns with King Machine's commitment to proactive tire sipe and mold development, in collaboration with their top customers.

The decision to select the AddUp FormUp 350 platform was driven by its proven success in the tire industry. The FormUp 350 is currently employed for the serial production of tire sipes, demonstrating its reliability and efficiency in an industrial manufacturing environment. The machine's higher throughput and lower total cost of ownership were significant factors in the decision. Its 350 mm platform, 4-laser system, delivers double the output when compared to the competition. This results in substantial operational cost savings through reduced labor, fewer post-processing steps, and faster machine turnover.

“We chose the AddUp FormUp 350 because of its exceptional performance and cost efficiency” explains King Machine’s CEO Michael Wells. “This machine not only meets our high-quality standards but also enhances our operational capabilities, ensuring we remain at the forefront of the tire mold manufacturing industry.”

King Machine takes immense pride in being a US company with 100% domestically built products. And the addition of the FormUp 350 PBF machine to their 80,000 square foot facility represents a significant investment in advanced manufacturing technologies. As part of their ongoing expansion, they continue to leverage their 70 years of mold manufacturing expertise to serve markets in addition to the tire industry.

Sarah Plummer

AddUp

+1 5137454510

email us here

Visit us on social media:

X

LinkedIn

YouTube

1 http://www.kingmachinemolds.com/

2 https://addupsolutions.com/

3 https://addupsolutions.com/machines/pbf/formup-350/