Electro Scan Inc.'s 750 Leaks per Mile Becomes Water Industry's 'Most Accurate Leak Detection' Solution

Electro Scan Becomes 'Most Accurate Leak Detection Solution' Finding on Average over 750 Leaks per Mile.

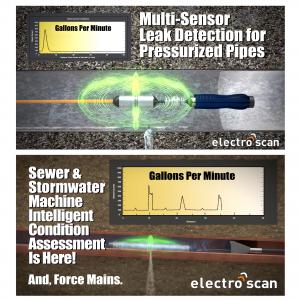

All leaks are located and measured in Gallons per Minute or Liters per Second, without relying on 'seeing' or 'hearing' defects at Joints, Customer Tap Locations, or Pipe Walls.

1cm Locational Accuracy Combined With Leaks Expressed in GPM or LPS Means More Targeted Repairs, Minimizing CAPEX, and Dramatically Lowered Unit Costs Per Leak

Unit costs for recent untethered acoustic ball pipe inspection projects suggest a $4,000 cost for each leak detected, compared to a $30 cost per leak using Electro Scan's multi-sensor machine-intelligent tethered in-pipe inspection solution.

More importantly, Electro Scan's ability to then estimate each leak's potential defect flow rate in Gallons per Minute (GPM) or Liters per Second (LPS), eliminates the guesswork in setting rehabilitation and capital planning priorities, and represents a major competitive solution.

Last month, Electro Scan Inc. was named 'Leak Detection Solution of the Year' for 2021 by IoT Breakthrough3 for its game changing ability to measure accurate locations and estimate the severity of those leaks in GPM or LPS.

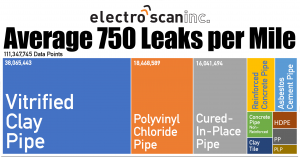

Electro Scan's pipe inspection results since 2011 include over sixty (60) different pipe materials, where over 110 million data points have been generated in testing pipe walls for leaks, wall thickness, joint separation, leaks at service connections, and verifying that newly installed or rehabilitation pipes are watertight.

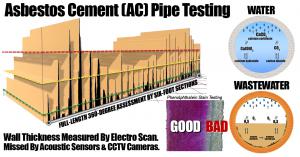

Asbestos Cement Pipe (ACP), High Density Polyethylene (HDPE), Polyvinyl Chloride (PVC), Vitrified Clay Pipe (VCP), and newly installed Cured-In-Place Pipe (CIPP) liners have been the most common pipes tested by the company's FELL technique, including both pressurized & gravity pipes.

Many cities dealing with unsustainable levels of Non-Revenue Water (NRW), higher sewer infiltration rates, and the impact of climate change, have determined that contractor-friendly pipeline acceptance standards often allow significant leakage rates when first commissioned.

Often based on visual inspection, alone, Electro Scan has emerged as a new tool to certify full length pipes, including Trenchless cured-in-place pipe (CIPP), to minimize leakage and ensure pipe do not more AFTER rehabilitation, then BEFORE rehabilitation, especially if contractors cause damage to host pipes during the reconnection of service connections.

Electro Scan's new Delta probe system provides for collecting three (3) data sets, including Acoustic signals, CCTV video images, and Low Voltage Conductivity, or FELL data, with each of its pipe surveys. A key feature of the inspection is that the pipe remains in service, without dewatering or bypass pumping, and allows the company to not only estimate the potential flow from each leak along 360-degrees of the pipe’s full length, but also estimate angular joint misalignment, defect lengths, joint coupling spacing, ovality, as well as pipe leaching and pipe wall thickness for ACP.

In contrast to traditional leak detection devices that rely on field operators to see or hear leaks, Electro Scan's patented multi-sensor tethered probes precisely locate leaks to within 3/8th of an inch (1cm), estimate flow rates in GPM or LPS, and are not dependent on pipe pressure conditions to document leak sizes. Moreover, data collection and processing is fully automated and does not rely on operator interpretation or bias.

"Electro Scan's discovery of about '750 Leaks per Mile,' coupled with locating each leak with 1cm accuracy, without temporary dewatering or bypass pumping, is unprecedented," stated Paul Pasko, P.E., Vice President, International Business Development. "Its ability to estimate small leaks from large leaks in Liters per Second or Gallons per Minute, is also impressive."

Recent published results from Electro Scan compared to other traditional leak detection solutions, show the following:

LEAKS PER MILE

o Electro Scan Tethered Probe about 750

o Satellite Screening, Plus Acoustic Hydrophone 3.9

o Acoustic Tethered & Untethered Balls 1.6

LEAKS PER KILOMETER

o Electro Scan Tethered Probe about 470

o Satellite Screening, Plus Acoustic Hydrophone 2.4

o Acoustic Tethered & Untethered Balls 1.0

According to the American Society of Civil Engineers, there are over 240,000 water main breaks annually in the US alone, resulting in an estimated cost of more than $6 billion. Most water main breaks are inspected either by independent contractors or water utility crews.

"After nearly three decades of using a variety of acoustic devices, many people are learning the limitations of using in-pipe acoustic devices," stated Chuck Hansen, Chairman & CEO, Electro Scan Inc.

"Especially when catastrophic water main breaks occur soon after leak detection2 crews had just evaluated those same pipes," stated Hansen.

At the company's current rate of growth, Electro Scan is expected to become the water industry's largest CCTV inspection provider for pressurized pipe.

While typically used for navigational purposes inside the pipe, the high-resolution camera also allows the company to identify obstructions in pipes, such as heavy tuberculation, closed valves, junctions, and illegal tap connections.

These high-resolution cameras, coupled with Hansen Analytics' Artificial Intelligence (AI) and Machine Learning (ML) data processing, additionally allows Electro Scan Authorized Service Providers (ASPs) to measure pipe ovality, angular misalignment, joint separation, defect lengths, and service tap locations.

Accessible from its award-winning CriticalH2O® & CriticalSewers® cloud applications, pipe inspection data is available in minutes, and in multiple languages, including English, Arabic, Mandarin Chinese, Hindi, and Japanese with measurements in both English and SI units.

Application Programming Interfaces (APIs) also allows Electro Scan’s inspection data to seamlessly integrate with Geographic Information System (GIS) platforms and other asset management software solutions to provide more accurate estimates of Likelihood of Failure (LoF), Consequence of Failure (CoF), and Remaining Useful Life (RUL) to assist with critical rehabilitation decision making.

Electro Scan Inc. will be entering the commercial plumbing market in 2021 as it develops probes able to find leaks in 1-2 inch (25-50mm) pipe diameters. Since many service connections and homes have plastic pipes, few acoustic sensors are capable of hearing leaks, let alone determining their severity.

ABOUT ELECTRO SCAN INC.

Founded in 2011, the company designs machine-intelligent leak detection products that help utilities locate leaks in pressurized water mains and gravity wastewater pipes & force mains/rising mains to pinpoint sources of Non-Revenue Water and certify new pipe installations and rehabilitation as watertight. Headquartered in Sacramento, California, the company sells equipment to utilities and licenses its solutions to contractors on a Technology-as-a-Service basis, worldwide.

Hashtags

#acoutics #acousticsensors #acp #ai #amp7 #artificialintelligence #asce #awwa #cipp #climatechange #conditionassessment #conductivity #deeplearning #drainage #drought #electromagnetic #fell #hdpe #infrastructure #innovyze #inspection #leak #leakdetection #machinelearning #ml #nassco #pacp #pcat #pe #piperepair #plasticpipe #pressuretransient #pvc #resilient #resiliency #sewer #sewerai #swan #trenchless #utilities #vcp #wastewater #water #waterai #wsaa #worldbank #wsaa

Carissa Boudwin

Electro Scan Inc.

+1 916-779-0660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

1 http://www.electroscan.com

2 https://www.electroscan.com/wp-content/uploads/2021/01/Water-Competitor-Projects_8-pgs.pdf

3 https://www.electroscan.com/wp-content/uploads/2021/01/2021-01-11_Leak-Detection-Solution-of-the-Year.pdf