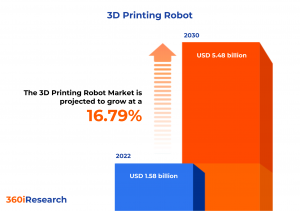

3D Printing Robot Market worth $5.48 billion by 2030, growing at a CAGR of 16.79% - Exclusive Report by 360iResearch

The Global 3D Printing Robot Market to grow from USD 1.58 billion in 2022 to USD 5.48 billion by 2030, at a CAGR of 16.79%.

PUNE, MAHARASHTRA, INDIA , December 6, 2023 /EINPresswire.com/ -- The "3D Printing Robot Market by Offering (Components, Services, Software), Material (Ceramic, Metal, Polymer), End User, Application - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global 3D Printing Robot Market to grow from USD 1.58 billion in 2022 to USD 5.48 billion by 2030, at a CAGR of 16.79%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/3d-printing-robot?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

A 3D printing robot is an automated, programmable machine or robotic arm equipped to perform 3D printing tasks. 3D printing robots offer enhanced flexibility and range of motion, allowing the production of larger and more complex structures with greater efficiency and precision. These robots integrate additive manufacturing techniques by extruding materials to create 3D objects from a digital file. The growing demand for customized and intricate component designs is accelerating the use of 3D printing technologies across various industries, including aerospace, automotive, healthcare, and construction. Additionally, the inclination toward advanced manufacturing technologies and Industry 4.0 solutions encourages the adoption of 3D printing robots by the end-use sectors globally. However, high initial investment for setting up and integrating 3D printing robots can prevent small and medium enterprises (SMEs) from adopting this technology. Moreover, technological advancements to enhance the efficiency and accuracy of 3D printing robots are anticipated to encourage their use in the end-use industries worldwide.

Offering: Significant penetration of robotic arms in 3D printing robots

The 3D printing robots comprise components such as heated build plates, pellet extruders, and robotic arms that aid in conducting various functions in manufacturing facilities. The heated build plate is a critical component of a 3D printing robot that fabricates three-dimensional objects and is constructed from durable materials that can withstand high temperatures to ensure proper adhesion of the initial layers of extruded material, preventing warping and improving the quality of the print. Its temperature can be controlled to cater to various thermoplastic materials used for printing. By maintaining a consistent thermal environment, the heated build plate significantly reduces the chances of printing errors, contributing to a more reliable 3D printing process. The pellet extruder is an integral component designed for 3D printing robots that can directly consume raw thermoplastic pellets instead of the traditionally used filament. This leads to substantial cost savings owing to the lower price of raw materials and also allows for greater material flexibility and the potential for mixing custom blends of materials. The pellet extruder heats and melts the pellets, forcing the molten plastic through a nozzle to create the object's layers. Advanced models of pellet extruders can offer high extrusion rates, which facilitates faster printing times and is particularly beneficial for large-scale manufacturing and prototyping operations where efficiency is a primary concern The anthropomorphic arm mimics human arm movement capabilities, offering a versatile solution to 3D printing. It can perform complex tasks that require a range of motions, positioning the printing head with high precision across multiple axes. Articulated arm robots include a rotary joint layout, similar to a human arm, which allows for enhanced flexibility. With multiple independent axes of rotation, they can maneuver around obstacles and are ideal for 3D printing tasks requiring intricate designs and high skill levels. Cartesian arms offer an axis-aligned approach to 3D printing, moving linearly along the X, Y, and Z axes. This ensures consistent performance and precision for jobs that demand uniform, grid-like movement paths. Cartesian arms produce parts that require strict adherence to dimensional tolerances. A parallel arm consists of interconnected arms supporting a common base. They are fast and extremely precise, capable of rapid and accurate placement of the printing head. They are often used in rapid prototyping and large-scale 3D printing installations. Selective Compliance Assembly Robot Arm (SCARA) robots are designed to offer selective compliance in arm assembly, favoring vertical rigidity with horizontal flexibility. This makes them highly effective for 3D printing tasks requiring gentle handling and precision in horizontal assembly operations. Six-axis arms deliver an extensive range of motion, allowing pivot at six different points. Their flexibility enables the easy production of highly complex geometries and finishing surfaces, making them useful in multi-directional 3D printing applications. 3D printing robot services offer diverse applications, such as rapid prototyping, where end-use industries benefit from the speedy production of scale models or parts. In addition, they are utilized for final product manufacturing, offering customization and complexity in products that traditional manufacturing methods cannot achieve. Maintenance, repair, and overhaul (MRO) services use 3D printing robots to refurbish and repair components, ensuring longevity and reliability. Advanced software solutions are integral to operating 3D printing robots providing design, visualization, and control tools. These software platforms enable the optimization of print parameters, real-time adjustments, and seamless integration with various robotic systems, greatly enhancing the efficiency and quality of 3D printing operations.

End User: Expanding use for the development of automotive components

3D printing robots are revolutionizing the aerospace & defense industry by enabling the production of complex components that are lighter and stronger. These robots facilitate the creation of parts with intricate geometries that are impossible to manufacture using traditional methods. In the automotive industry, 3D printing robots produce prototype and production parts, including complex engine components, lightweight structural elements, and personalized interior features. This technology enhances the flexibility of manufacturing operations, supporting the growing demand for customization and enabling automakers to implement just-in-time production strategies. The construction industry significantly benefits from integrating 3D printing robots, particularly in prefabricated building components and constructing complex architectural features. These robots can construct structures directly on-site, reducing the reliance on skilled labor, accelerating construction timelines, and lowering overall project costs. In addition, 3D printing in construction promotes sustainability through the precise utilization of materials and the ability to create energy-efficient designs. The consumer products industry uses 3D printing robots for mass customization, allowing manufacturers to offer personalized products without significant additional costs. From custom footwear to tailored toys and accessories, 3D printing robots enable the direct fabrication of consumer goods from digital files, streamlining the production process. Electronics manufacturers use 3D printing robots to fabricate complex components such as circuit boards, sensors, and connectors. This technology allows for integrating electronic functionality into parts during the build process, potentially revolutionizing the design and manufacturing of electronic devices. The precision and versatility of 3D printing robots support the miniaturization trend in electronics, creating more compact, lightweight, and powerful devices. In the energy sector, 3D printing robots manufacture parts for renewable energy systems, including wind turbine blades and solar panel components. The oil & gas industry employs these robots to create complex drilling tools and custom pipeline fittings designed to endure harsh operational environments. The adaptability of 3D printing robots to produce components on demand minimizes downtime and can significantly enhance the efficiency and sustainability of energy production. The healthcare industry uses 3D printing robots to create patient-specific implants, prosthetics, and anatomical models for preoperative planning. The precise customization capabilities of 3D printing technologies are critical in achieving better patient outcomes and advancing personalized medicine. Furthermore, 3D printing robots are utilized in developing innovative medical devices and laboratory equipment and in the pharmaceutical industry for printing drugs with complex dosage forms and release profiles. Other applications of 3D printing robots include their support to educational institutions and research facilities in creating intricate models for study and experimentation. In the textile industry, they create unique and intricate artwork, apparel, and accessories. Additionally, edible products can be crafted with these robots in the food industry, allowing for innovative shapes and designs in the culinary arts.

Application: Proliferating use of 3D printing robots for functional part manufacturing

3D printing robots are enabling the direct production of functional parts. This technology allows a streamlined transition from design to manufacturing, significantly reducing production time and cost. Robots can produce parts that meet the strength, durability, and complexity requirements for end-use in various industries, ranging from aerospace to consumer goods, with advanced materials and precise printing techniques. The versatility of 3D printing robots makes them ideal for rapid prototyping. They allow designers and engineers to quickly create and test the physical models of their designs. This accelerates the development process and helps identify potential design defects early, facilitating faster testing and innovation. Prototyping with 3D printing robots can significantly reduce the time to market for new products. 3D printing robots are extensively used in tooling applications. They can manufacture custom jigs, fixtures, and molds without conventional tooling methods' traditional cost and time constraints. This application is particularly beneficial for low-volume or customized production, where it is not cost-effective to invest in hard tooling. Companies can achieve high customization and flexibility in their manufacturing processes by using 3D printing robots.

Regional Insights:

The 3D printing robots market is growing in the Americas due to the demand for advanced manufacturing techniques and customization in the aerospace, automotive, and healthcare sectors. Increasing focus on enhancing precision and speed, while government initiatives often aim to support domestic manufacturing capabilities in the Americas. EU countries strongly emphasize the innovation and integration of 3D printing robots into existing industrial infrastructures. The Middle East is increasingly recognizing the potential of 3D printing robots in sectors such as construction and medicine. The unique consumer need in this region gravitates toward the customization capabilities of 3D printing in architectural projects and the healthcare sector, leveraging significant investments in cutting-edge technologies. In Africa, the 3D printing robotics market is in the nascent stages; however, the growing need for infrastructure development and manufacturing advancements is creating immense potential for the 3D printing robot market. Increasing interest in improving manufacturing capabilities and government support to localize production and boost the manufacturing sector is propelling the use of advanced technologies such as 3D printing robots in the APAC region.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the 3D Printing Robot Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the 3D Printing Robot Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the 3D Printing Robot Market, highlighting leading vendors and their innovative profiles. These include ABB Ltd., ADAXIS SAS, ADDICT3D, CEAD B.V., Comau S.p.A., Continuous Composites Inc., Denso Corporation, Desktop Metal, Inc., Divergent Technologies, Doosan Robotics Inc., Dyze Design, Inc., Engineering Technique, FACFOX, INC., Fanuk Corporation, Hans WEBER Maschinenfabrik GmbH, Hyperion Robotics Oy, Hypertherm, Inc., Innse-Berardi S.p.A., iRobot Corporation, Kawasaki Heavy Industries, Ltd., KUKA AG, Massive Dimension, Meltio3D, MX3D, Omron Corporation, Orbital Composites Inc., Siemens AG, Titan Robotics Inc., Universal Robots A/S, Vertex Dynamix LLC., VOiLA3D, Yaskawa Electric Corporation, and Yizumi Holdings Co., Ltd..

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/3d-printing-robot?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the 3D Printing Robot Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Offering, market is studied across Components, Services, and Software. The Components is further studied across Heated Build Plate, Pellet Extruder, and Robotic Arms. The Robotic Arms is further studied across Anthropomorphic Arm, Articulated Arm, Cartesian Arm, Parallel Arm, and Selective Compliance Assembly Robot Arm. The Services is projected to witness significant market share during forecast period.

Based on Material, market is studied across Ceramic, Metal, and Polymer. The Ceramic is projected to witness significant market share during forecast period.

Based on End User, market is studied across Aerospace & Defense, Automotive, Construction, Consumer Products, Electronics, Energy, and Healthcare. The Automotive is projected to witness significant market share during forecast period.

Based on Application, market is studied across Functional Part Manufacturing, Prototyping, and Tooling. The Tooling is projected to witness significant market share during forecast period.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Asia-Pacific commanded largest market share of 37.12% in 2022, followed by Europe, Middle East & Africa.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. 3D Printing Robot Market, by Offering

7. 3D Printing Robot Market, by Material

8. 3D Printing Robot Market, by End User

9. 3D Printing Robot Market, by Application

10. Americas 3D Printing Robot Market

11. Asia-Pacific 3D Printing Robot Market

12. Europe, Middle East & Africa 3D Printing Robot Market

13. Competitive Landscape

14. Competitive Portfolio

15. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the 3D Printing Robot Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the 3D Printing Robot Market?

3. What is the competitive strategic window for opportunities in the 3D Printing Robot Market?

4. What are the technology trends and regulatory frameworks in the 3D Printing Robot Market?

5. What is the market share of the leading vendors in the 3D Printing Robot Market?

6. What modes and strategic moves are considered suitable for entering the 3D Printing Robot Market?

Read More @ https://www.360iresearch.com/library/intelligence/3d-printing-robot?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+1 530-264-8485

ketan@360iresearch.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.