DCS Demonstrating New Digital Twin for Gear Systems to Reduce Tooling Changes, Testing, and Improve Gear Performance

DCS Shows New Digital Twin Technology for Gears to Reduce Costs, Testing, and Prototypes in Free Webinar and Whitepaper

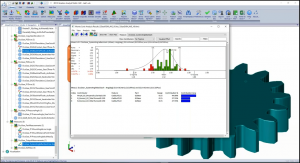

The webinar shows how a CAD Digital Twin can use 3DCS Variation Analyst software to validate the design and tolerancing of an individual gear. This method uses Monte Carlo simulation for running standard tests and gear specification measurements, predicting results as deviation from nominal values and predicted range of values. This analysis, along with analysis metrics, contributors, risk of failure, combine to give engineers the information needed to make decisions about design, manufacturing processes, and assembly that reduce the chances of problems as well as the number of physical tests and prototypes needed to optimize the design itself.

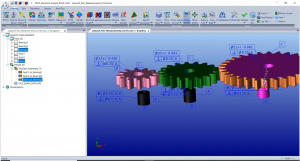

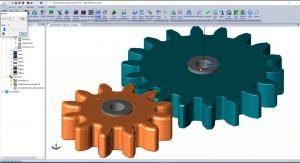

3DCS Variation Analyst software is a CAD integrated tolerance stack-up simulation tool developed by DCS. Integrated into all the major CAD platforms, CATIA, CREO, SOLIDWORKS, NX, 3DEXPERIENCE, 3DCS software provides real insight into both the risk of failure from variation and the sources of variation within an assembly. As inputs, 3DCS uses part tolerances, often represented using GD&T, as well as assembly processes and assembly sequences. In order to handle gears and other mechanical components, 3DCS leverages an Add-on; Mechanical Modeler, which includes a unique tool called the 3DCS Gear Module. This allows users to simulate gear contact surfaces and standard tests, both at a stationary position and through gear rotations.

The 3DCS Gear Module now provides additional predictions which include Multi-tooth contact with gear rotation. The location of the tooth-to-tooth in multi-tooth contacts corresponds to the Flank Test results. Additionally, the Digital Twin model provides performance validation of gear assemblies including the standard tests: Total Composite Deviation, and Single Pitch Deviation. These tests are in addition to measurements for Axial Backlash, Angle Backlash, and Pressure Angle.

The 3DCS Gear Module has also been enhanced to simulate a Rolling Gear Gage to measure the Total Radial Composite Deviation. In the simulation model, the Master Gear Rotates, and the Work Gear is pressed against it, forcing contact at two locations, which will change as rotation occurs and new teeth come into contact.

The results for Gear Tests and studies are calculated from the measurement distance between gear centers. In addition to this measurement, the angular deviation between teeth is also taken into account. These tests, leveraging the Digital Twin, provide savings by avoiding tooling changes and by optimizing the gear parameters, such as crowning.

To see the crowned spur gear model and results yourself, and get access to a free whitepaper about the process, join the DCS webinar on January 27th, 2022. Register at https://mkt.3dcs.com/gear-model-simulation-webinar-2022. Learn more about DCS’ software and services at https://www.3dcs.com.

About DCS

DCS has been supporting quality management in industries including automotive, aerospace, medical device, electronics, and industrial machinery for over 20 years. DCS solutions are used daily by companies like Airbus, BMW, GM, LG, Nissan, Phillips, Sony, Textron Aviation, and VW. By applying DCS's 3D Model-Based environment for Predictive Variation Analysis and Responsive SPC, manufacturers have reduced quality costs related to yield, scrap, rework and warranty issues. Read more at https://www.3dcs.com.

Benjamin Reese

Dimensional Control Systems

+1 2482699777

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Example Digital Twin Model in CAD with 3DCS software

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.