Lignin-Based Sunscreen Offers Natural and High-Performance UV Protection

NANJING, CHINA, September 29, 2024 /EINPresswire.com/ -- In a significant breakthrough for the cosmetics industry, researchers have developed a new type of sunscreen using lignin, a naturally abundant polymer, and titanium dioxide (TiO2). The study, led by Yarong Li and Zhiguang Tang, was published in the Journal of Bioresources and Bioproducts and details the innovative use of a dual-modified lignin sub-microsphere to enhance the SPF and improve the color of sunscreens.

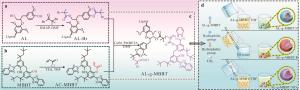

Lignin, a byproduct of the pulp industry, is known for its UV-absorbing properties and antioxidant capabilities. However, its application in commercial sunscreens has been limited due to its low SPF and dark coloration. To address these challenges, the researchers conducted a dual modification of lignin's chemical structure and physical form. They grafted methylene bis-benzotriazolyl tetramethylbutylphenol (MBBT) onto alkali lignin (AL) to create a polymer, AL-g-MBBT. This polymer was then transformed into sub-micron spheres with and without TiO2 loading.

The results were impressive. Sunscreens prepared with 10% AL-g-MBBT3 demonstrated an SPF of 42.93, a significant increase from the 4.74 SPF of unmodified AL. Moreover, the color of the modified lignin-based sunscreen was considerably lighter, with a color difference value (ΔE) of 45.6, compared to the 49.5 ΔE of unmodified AL, making it more appealing for cosmetic use.

The researchers further improved the sunscreen's performance by creating TiO2-loaded sub-micron spheres. These AL-g-MBBT3/TiO2@C sunscreens achieved SPFs of 66.20, outperforming both the unmodified AL and the sub-micron spheres without TiO2 loading. The color of these sunscreens was also significantly improved, with a ΔE value of 36.3.

The study also evaluated the photostability and biocompatibility of the lignin-based sunscreen. The results showed that the sunscreen maintained its sun protection performance and color even after three hours of UV irradiation. Additionally, the biocompatibility tests indicated that the modified lignin-containing sunscreen was non-toxic to human keratinocytes, suggesting it is safe for use on the skin.

This research presents a significant advancement in the application of lignin, offering a sustainable and high-performing alternative to traditional sunscreen ingredients. The findings could pave the way for a new generation of eco-friendly and effective sunscreen products.

See the article:

DOI

https://doi.org/10.1016/j.jobab.2024.09.003

Original Source URL

https://www.sciencedirect.com/science/article/pii/S2369969824000574

Lignin, a byproduct of the pulp industry, is known for its UV-absorbing properties and antioxidant capabilities. However, its application in commercial sunscreens has been limited due to its low SPF and dark coloration. To address these challenges, the researchers conducted a dual modification of lignin's chemical structure and physical form. They grafted methylene bis-benzotriazolyl tetramethylbutylphenol (MBBT) onto alkali lignin (AL) to create a polymer, AL-g-MBBT. This polymer was then transformed into sub-micron spheres with and without TiO2 loading.

The results were impressive. Sunscreens prepared with 10% AL-g-MBBT3 demonstrated an SPF of 42.93, a significant increase from the 4.74 SPF of unmodified AL. Moreover, the color of the modified lignin-based sunscreen was considerably lighter, with a color difference value (ΔE) of 45.6, compared to the 49.5 ΔE of unmodified AL, making it more appealing for cosmetic use.

The researchers further improved the sunscreen's performance by creating TiO2-loaded sub-micron spheres. These AL-g-MBBT3/TiO2@C sunscreens achieved SPFs of 66.20, outperforming both the unmodified AL and the sub-micron spheres without TiO2 loading. The color of these sunscreens was also significantly improved, with a ΔE value of 36.3.

The study also evaluated the photostability and biocompatibility of the lignin-based sunscreen. The results showed that the sunscreen maintained its sun protection performance and color even after three hours of UV irradiation. Additionally, the biocompatibility tests indicated that the modified lignin-containing sunscreen was non-toxic to human keratinocytes, suggesting it is safe for use on the skin.

This research presents a significant advancement in the application of lignin, offering a sustainable and high-performing alternative to traditional sunscreen ingredients. The findings could pave the way for a new generation of eco-friendly and effective sunscreen products.

See the article:

DOI

https://doi.org/10.1016/j.jobab.2024.09.003

Original Source URL

https://www.sciencedirect.com/science/article/pii/S2369969824000574

Journal of Bioresources and Bioproducts

Nanjing Forestry University

02585426289

email us here

Visit us on social media:

Facebook

X

LinkedIn

Instagram

YouTube

Other