Innovative Light-Driven Enzymatic Biosystem for the Synthesis of Natural Terpenoids

USA, July 1, 2024 /EINPresswire.com/ -- In a recent study, researchers from China have developed a light-driven in vitro enzymatic1 system to produce α-farnesene, a useful natural terpenoid, from methanol. By optimizing and coupling thirteen biocatalytic reactions, and using natural thylakoid membranes, they achieved a significant α-farnesene production using methanol and glycolaldehyde as source materials. This method provides a promising, green alternative for synthesizing valuable terpenoids, highlighting its potential for future sustainable biochemical production platforms.

Terpenoids, such as α-farnesene, are natural compounds widely used in flavoring agents, fragrances, and even in biofuels. Traditionally, α-farnesene is extracted from plants, and hence their production may suffer from low yields and poor purity, unable to meet the criteria for human use. Chemical synthesis methods may address the above issues but can be challenging and harmful to the environment. Alternative methods using engineered microbes like cyanobacteria and Escherichia coli offer promising ways to produce α-farnesene from renewable sources and addressing these challenges.

In this vein, a group of researchers led by Professor Zhiguang Zhu from the Tianjin University of Science and Technology and the Chinese Academy of Sciences, have developed an innovative way to produce α-farnesene, using methanol and light. The findings of their study (doi: 10.34133/bdr.0039) were published on 21 June 2024 in BioDesign Research and promise an environmentally friendly and efficient process of α-farnesene production compared to traditional methods.

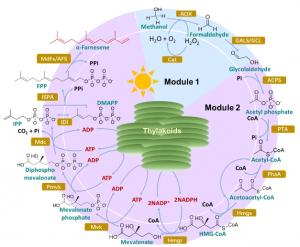

The key to this innovative method lies in the use of thylakoid membranes, which are components of plant cells that play a crucial role in photosynthesis and creating energy. By using these natural membranes, the researchers were able to create a system that mimics the way plants convert light energy into chemical energy, but for producing α-farnesene instead.

“Our study presents a route for the synthesis of α-farnesene based on an in vitro enzyme cascade reaction using methanol as an inexpensive and renewable carbon 1 (C1) substrate”, explains Prof. Zhu

The new process involves a series of 13 enzyme-driven reactions divided into two modules integrated with thylakoid membranes as a light-powered engine to convert methanol into α-farnesene. These membranes help to regenerate adenosine triphosphate and nicotinamide adenine dinucleotide phosphate hydrogen, which are energy molecules needed for enzymatic reactions. The use of light not only makes the process more sustainable but also more efficient.

The developed method not only harnesses renewable resources but also demonstrates potential for scalable industrial applications. By optimizing the concentration of enzymes, thylakoid membranes, and other cofactors, the researchers were able to achieve significant yields of α-farnesene, making this method a viable alternative to current production techniques. Additionally, the system's robustness under diverse light conditions underscored its adaptability.

“This study could provide a promising strategy for developing light-powered in vitro biosynthetic platforms to produce more natural compounds synthesized from C1 substrates,” Prof. Zhu notes, further stating, “This direction suggests future potential for C1 utilization and the engineering of photosynthetic cell factories for a variety of terpenes”.

Future modifications will be aimed at enhancing the efficiency and yield of terpenoid production, marking a significant stride in sustainable industrial practices. By harnessing the power of light and using renewable resources, this research expands possibilities for the production of valuable natural compounds in a way that is both environmentally friendly and economically viable.

Moreover, this study highlights the potential of innovative scientific approaches to address practical challenges while emphasizing the importance of sustainability in industrial processes. As industries increasingly seek greener alternatives, methods like this become crucial for reducing environmental impact and promoting sustainable development while setting a precedent for future innovations in synthesis of natural compound.

DOI

10.34133/bdr.0039

Original Source URL

https://spj.science.org/doi/abs/10.34133/bdr.00392

Lucy Wang

BioDesign Research

email us here

1 https://spj.science.org/doi/abs/10.34133/bdr.0039

2 https://spj.science.org/doi/abs/10.34133/bdr.0039