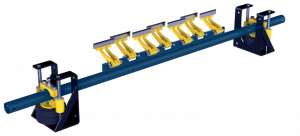

New Benetech Bxs5 Conveyor Scraper Blade with Tensioner Removes Belt Residue, Reduces Labor and Maintenance

Benetech, Inc. has announced the availability of its all-new BXS5 conveyor belt cleaner with a self-adjusting pneumatic tensioner.

AURORA, IL, USA, January 12, 2021 /EINPresswire.com/ -- Benetech, Inc. has announced the availability of its all-new BXS5 conveyor belt cleaner with a self-adjusting pneumatic tensioner as a solution to labor, housekeeping and system-wear challenges in bulk material handling.

Many bulk material handling operations use a primary scraper blade to clean conveyor belts during production. However, residual materials often remain on the belt. Primary conveyor scraper blades typically remove only 70% of initial carryback; clearing the leftover material requires a secondary belt cleaner.

Available in ceramic or tungsten carbide, Benetech’s BXS5 secondary conveyor scraper features overlapping individual blades with superior wear resistance for removing material residue and carryback. Its self-adjusting tensioner ensures constant blade-to-belt contact for consistent pressure on the belt. In addition to keeping the belt much cleaner, this adaptability cuts down on staff labor required to maintain optimal blade positions and pressure with other tensioner types.

The highly adaptable BXS5 conveyor scraper is also effective for use on spliced belts because it allows mechanical splices to pass without damage.

If the pneumatic tensioners are used for both the primary and secondary conveyor belt cleaner assemblies, they can be operated and automated by a single control panel.

“The BXS5 with the adjusting tensioner becomes a vital asset in a bulk material handler’s mission to minimize housekeeping and maintenance, as well as common problems such as belt mistracking,” said Benetech President and CEO Ron Pircon. “The BXS5 also adds to greater conveyor system longevity by extending the performance of both the conveyor belt and the belt cleaner.”

Benetech provides complete, performance-based solutions for dust mitigation and bulk material–handling systems. Its products, services and technologies reduce dust, prevent spillage, improve material flow and reinforce compliance. A partner in planning, engineering and operating dust-control and material-handling systems, Benetech helps companies assess challenges, establish priorities and achieve the results they require. For more information, please call (630) 844-1300 or visit www.benetechglobal.com.

Shannon Schurman

Benetech, Inc.

+1 630-844-1300

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.